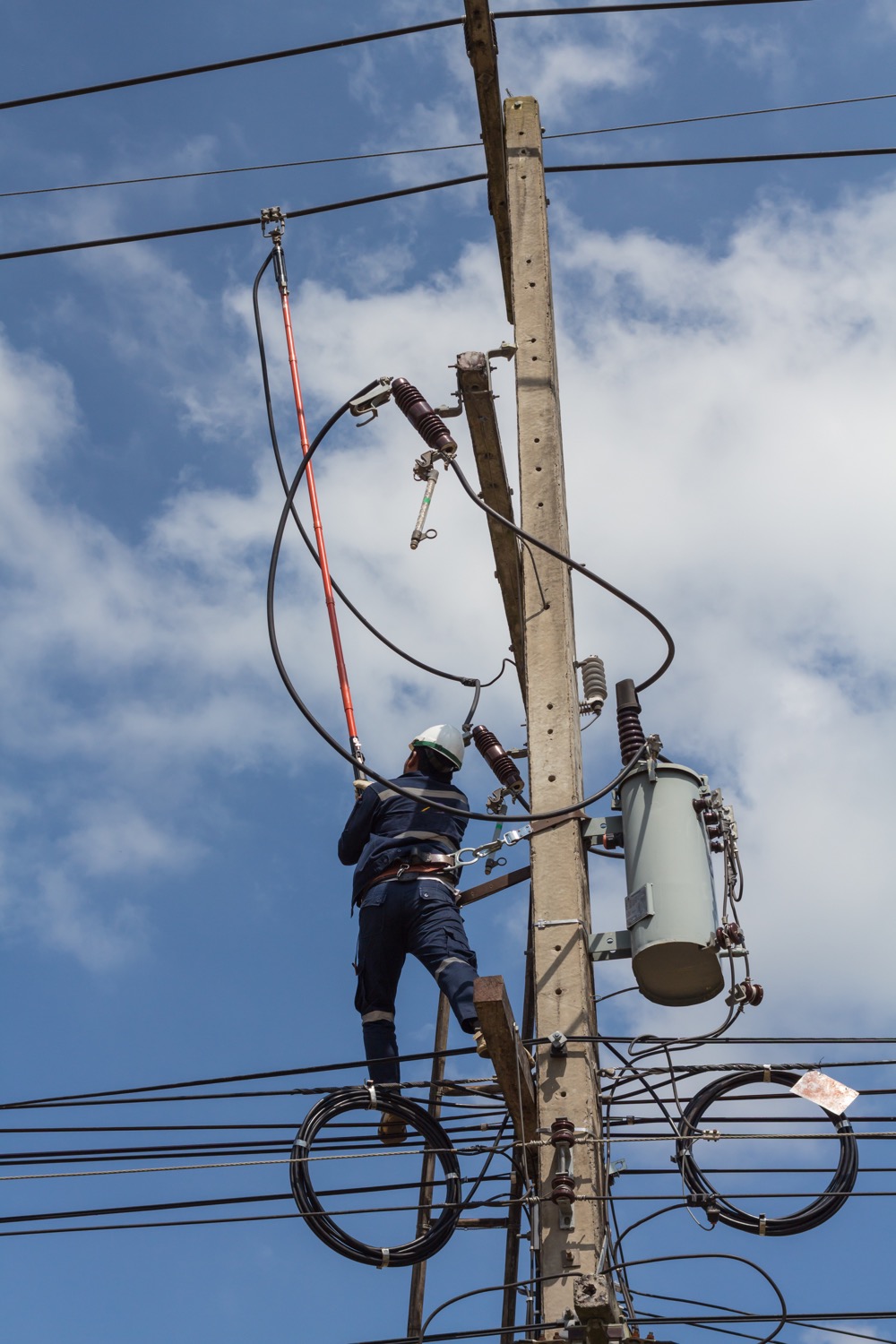

Hot sticks are insulated shaft with fittings on the ends which enable workers to adjust and manipulate live conductors and equipment from a safe distance. They come in varieties of length to serve different use and handle diverse voltage level of the charged equipment.

Today's Hot sticks are made of fiberglass. Previous designs were made from wood treated to be chemical, temperature and moisture resistant.

Here are some of the common types of hot sticks:

- Telescopic Hot Stick - are made of several hollow, tubular sections which perch inside of each other. It's top part can be extended and locked using a spring-loaded button that clicks open into a hole. It can be extended as many of the parts needed to carry out the work.

- Shotgun Stick - has a sliding lever mechanism that enables user to open and close the clamp hook at the end part of the stick. It lets the user fasten the stick to a disconnect ring then close it. The shotgun mechanism functions to unlock the hook when the switch is turned on.

- Universal Straight Stick - it allows different types of tools and equipment to be connected to the hot stick.

- Measuring Stick - provides easy and accurate method for infield measuring.

Since hot sticks are use when working with live line poles, it's important that these devices are subjected to regular hot stick insulation testing and maintenance. It must be done at least every 2 years. Seeking for a reliable testing company for electric materials, vehicle and other insulated equipment for electrical works, contact ETS Inspection and Testing Services.