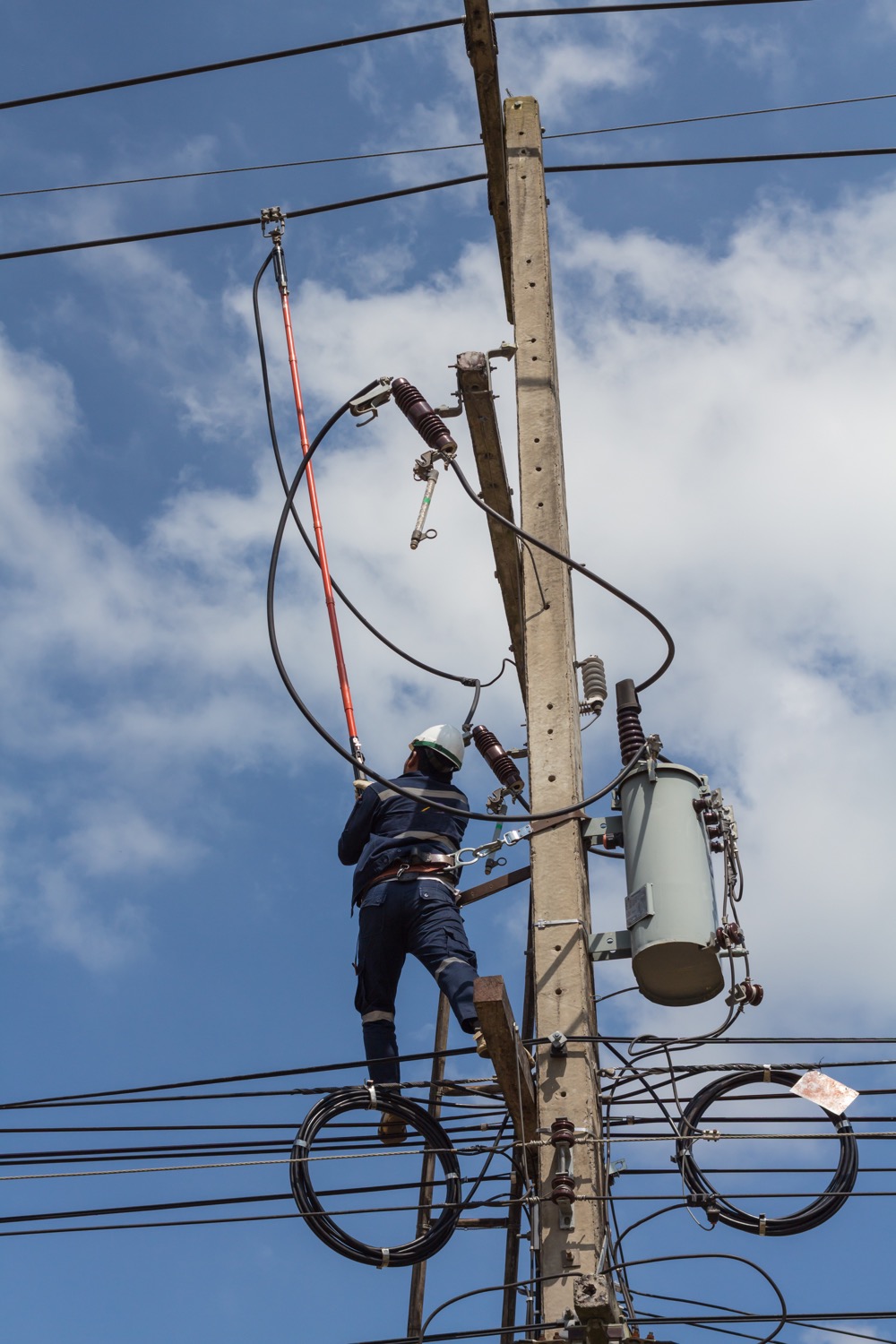

Electrical linemen is by nature one of the most dangerous occupations. They regularly put their lives at risk as they service live lines daily. Ensuring that all safety tools such as hot sticks work at optimal performance is crucial. To ensure this, regular and recurring dielectric testing service must be accomplished to protect both staff and electrical resources.

Are your hot sticks scratched or do they have a dull finish? Such conditions indicate that the stick is possibly unable to repel water and introduces a dangerous environment. That device could conduct current. You might be conducting dangerous business operations without even knowing it.

ETS Inspection and Testing Service offers full testing and hot stick repair service to ensure hot line tools are safe to use and perform optimally. These tools include Hot Line Stick equipment, Pruners, Fuse Pullers, etc. They are dielectrically tested for defects and malfunctions. The sticks are temporarily removed from the service to send it for repair and refinishing. After it is restored, it is once again tested dielectrically to evaluate its performance as it needs to pass the standards.

Certified technicians will diagnose the issue, find out the root cause, perform a comprehensive maintenance check and provide the quote. Mechanical defects, scratches, and cracks are then repaired. Refinishing process is done to return the tool to its original condition. It will undergo another dielectric test to ensure it passes the safety and performance standard. The tools are continued to be cleaned and maintained when it is returned to the field.

For more information about servicing, maintaining, and testing your hot sticks, contact ETS Inspection and Services.