Fusion splicing is increasingly popular for fiber optic termination. This is because of the process delivers excellent performance benefit while simultaneously providing protection against cable failure and weak signals. The result of which is the effective joining of two optical fibers end-to-end makes the light passing through the fibers intact and reflected back by the splice.

The process of fusion splicing is done with the coatings removed and the two bare fiber ends are fused together by heating with a high-voltage electric discharge. After heating them for a short time, the surface melts and pushes together until both ends are brought in close contact with a small gap in between. The pressure is in achieving a good alignment between the two fiber ends. In order to be precisely aligned the fibers before the splicing are ensured that the core matches well. It is to avoid the risk that the surface tension will pull the fiber ends towards a position other than the areas that have been matched.

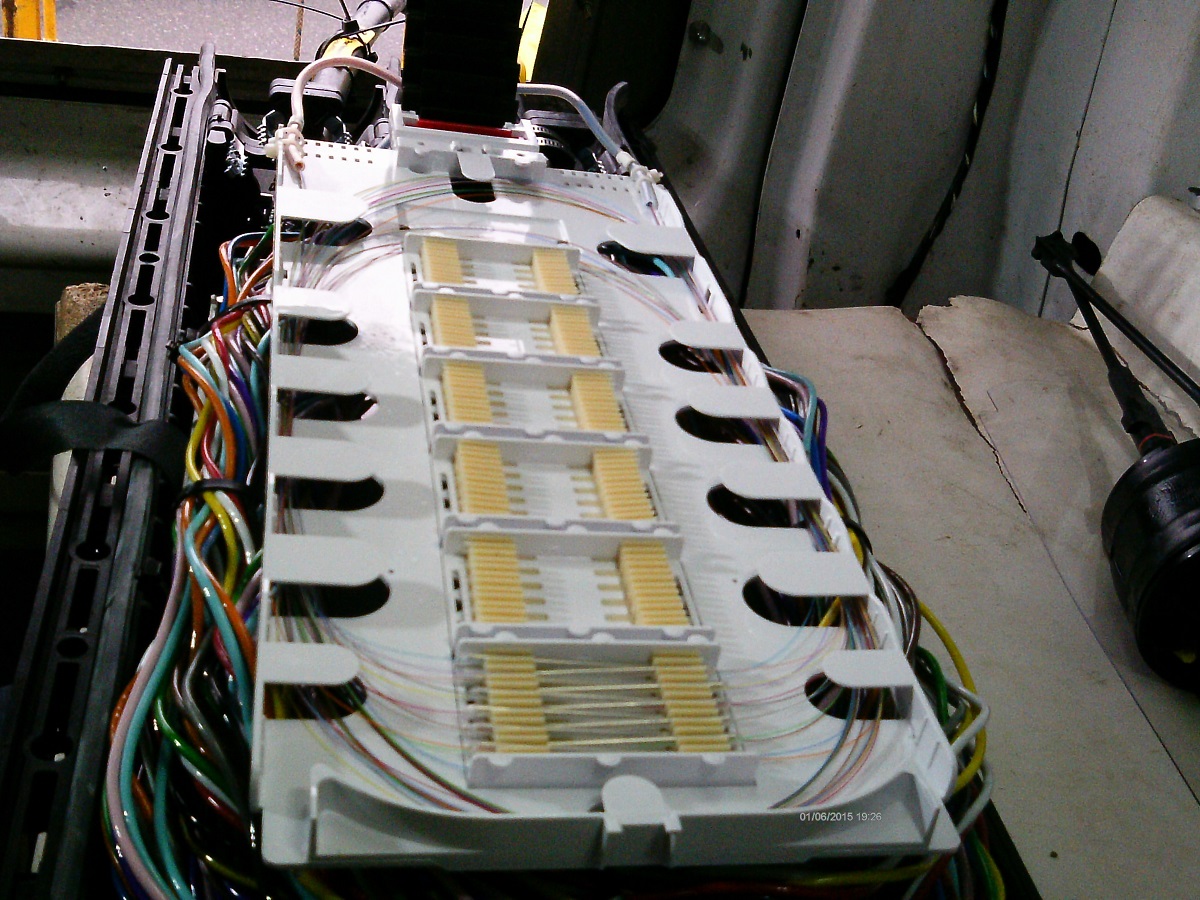

The fibers ends are normally prepared, split off and placed in alignment fixtures on the fusion splicer. The fusion splicer is the machine used to weld or fuse two optical fibers together. And to ensure utmost safety protection of the heated shrink splice sleeves is to store correctly in a proper storage that has ideal condition against moisture and other environmental hazards. By doing so, it will maintain its effectiveness and secure the fragile joints.

For more tips on Fusion splicing, contact ElecComm.