- Thursday, March 18, 2021

ElecComm Corporation (headquartered in Wilmington, Mass) has substantially grown and expanded its business serving all of New England and provides project management, design, engineering and end to end management expertise. ECC customers include but not limited to major utility companies, state and local government, communication service providers, government federally funded projects, municipalities and private entities.

Here is the list of our core competencies for you to consider:

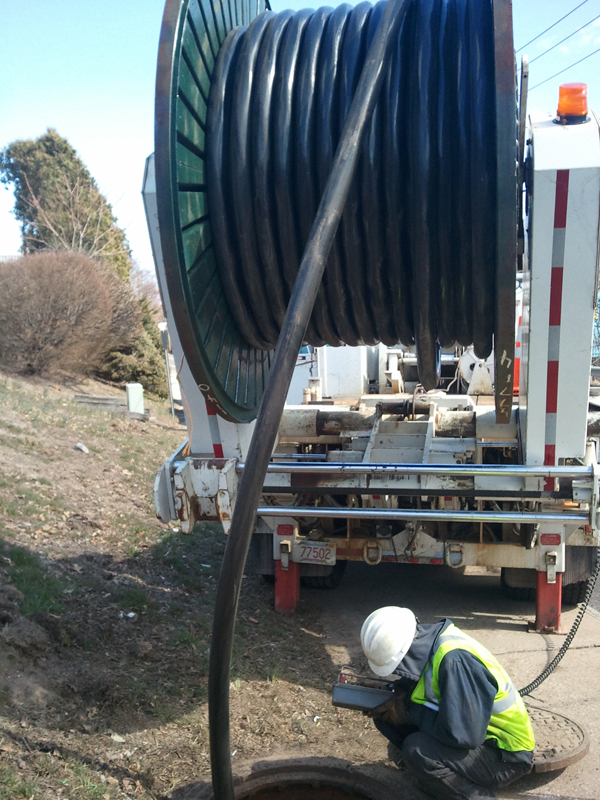

- Underground Electrical Construction

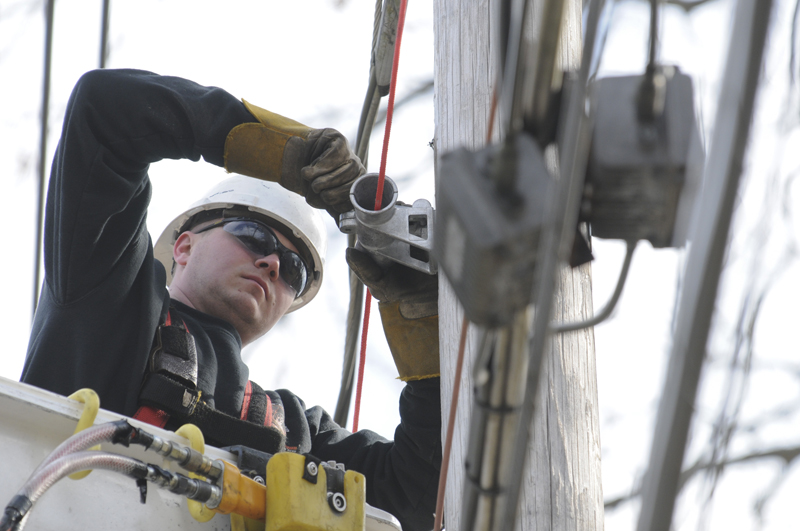

- Overhead Electrical Construction

- Scheduled Electrical Maintenance

- Emergency Electrical Restoration

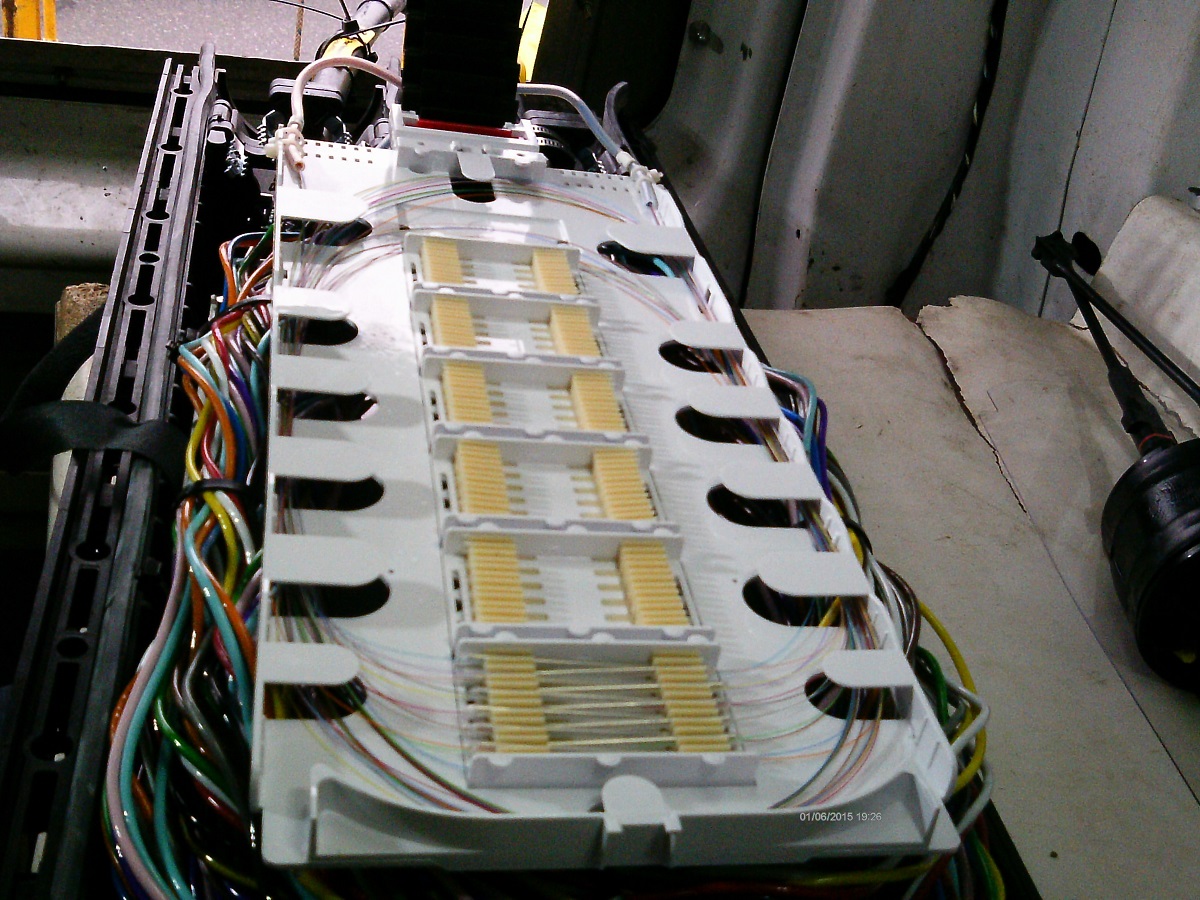

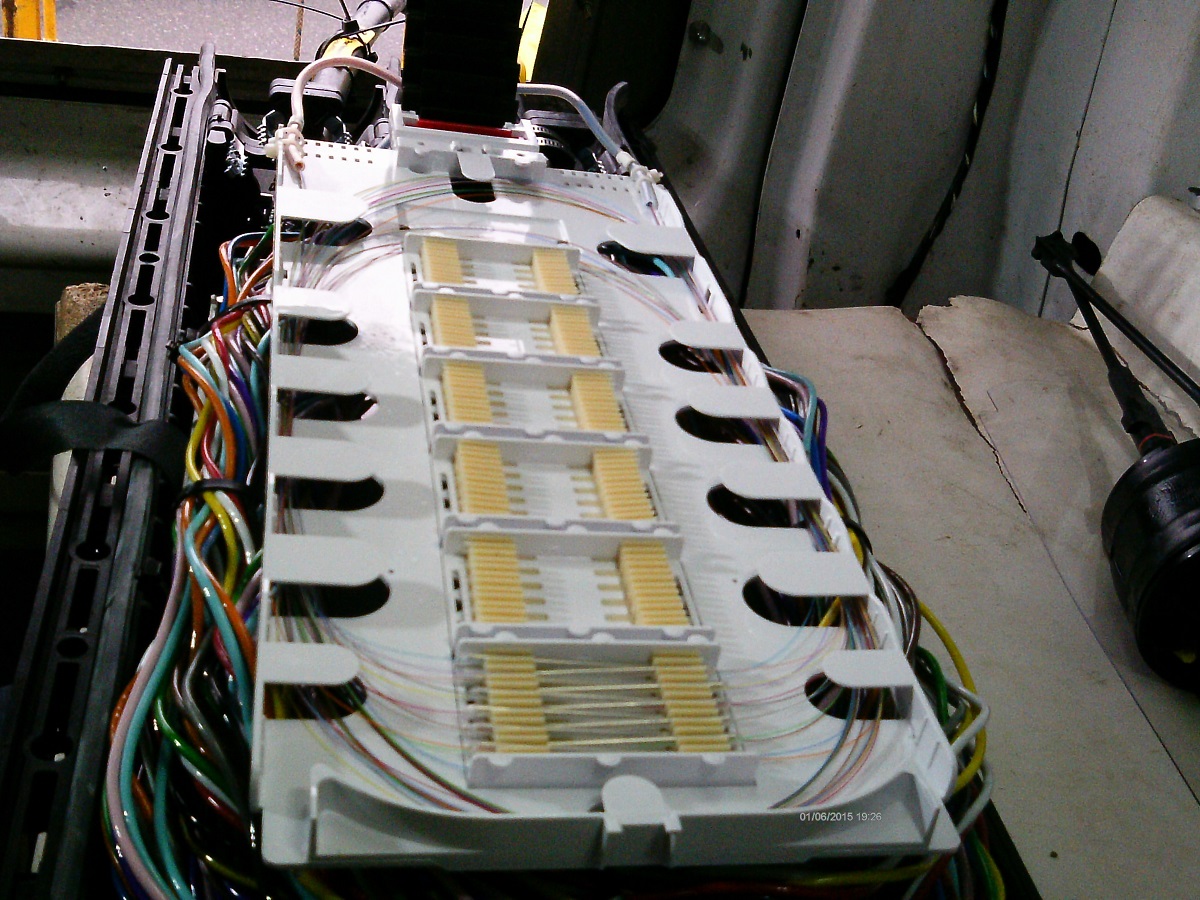

- Fiber Splicing

- Digital Network Testing

- Digital Network Installation

- Fiber Documentation

Our storm response team is available 24x7 for both overhead and underground emergency outages bringing power back to life for your customers. The crucial part of any business success is efficient, timely, and reliable communication within the organization and with the customers. And in maximizing the maintenance of the smooth day-to-day operation, telecom services provider makes it possible.

The transmission system of telecommunication networks facilitates the information to be transmitted in analog or digital form from different sites through electromagnetic signals. This information consists of audio or video data or some other types of data. During the transmission of information through digital and analog signals it transfers through electromagnetic waves. This is the reason why there are changes in frequency and amplitude when you play the music or images on the screen. And when you see some continuous waves that do not have any values it is an analog signal. Through this transmission of wireless data makes it possible by the radio waves. And the waves are generated naturally by generating vibration of electricity though it will be modified by their amplitude or frequency to transmit sound or data.

ElecComm has the ability to engineer, manage and perform the construction, splicing, testing maintenance, and restoration of fiber, copper, and hybrid fiber-coax telecommunications networks. To learn more about our telecommunication services, contact ElecComm.

- Wednesday, March 10, 2021

Job Responsibilities

- Demonstrate the habits of a safe and careful worker and become familiar with and practice all National Grid Safety Standards.

- Proficient in advanced splicing techniques, URD equipment, street light equipment, cable identification, rigging, pulling and racking.

- Assist in the training of lower classes and perform all tasks of lower classifications.

- Ability to perform the following duties:

- Build a 23kV PILC straight 3/C to 3/C straight splice, large sleeve lead-wiping use of steps, oil tapes. Read standards/charge out stock.

- Build a 15/23kV PILC trifurcating 3-1/C conductor to 3/C, large sleeve lead wiping of multiple joints with stress cones, oil tapes, stepping.

- Build 3/C PILC to 3-1/C solid dielectric heat shrink trifurcating splice. Ability to read/interpret manufacturer instructions of complex joints.

- Build a 15/23kV PILC half CTM splice. Ability to read instructions for CTM with an XLPE tap.

- Ability to properly break down paper and lead joints and construct a split sleeve for PILC joints.

- Build various splices for solid dielectric cables up to 35kV class, including heat shrink and cold shrink straight splices and terminators, H & Y pre-molded splices, and load break elbows.

- Review of all test equipment, prints and one-lines.

- Review of Tailboard Conference/Job Briefing and review of all safety equipment.

- Lead, plan and direct jobs as well as inspect and maintain tools and equipment.

- Trouble shooting skills with live voltage.

Job Qualifications:

- Must have at least two years of experience in the utility or related industry as a rated first class splicer.

- Successful applicant must past the EEI CAST test and pre-employment proficiency qualification test.

- Capable of working well with others in a team environment and as an individual contributor.

- Must successfully complete all department tests and acquire licenses and certificates including, but not limited to, System Hoisting Certificate, Clearance and Control Test, Asbestos License, etc.

- Requires exposure to inclement weather, temperature extremes, high noise levels, vibrations, electrical current, fumes and odors.

- Become familiar with construction, operating and maintenance standards and procedures.

- May be required to handle substances considered hazardous under the U.S. Emergency Planning and Community Right to Know Law or the Massachusetts Right to Know Law.

- May be required to work a reasonable amount of planned and emergency overtime, making available to supervisor an acceptable means of off-hour contact by telephone.

- Perform heavy work lifting and pulling over 100 pounds.

- Must be able to climb ladders, stairs, scaffolding, and use aerial bucket at construction sites.

- Must have and maintain a valid driver's license to operate vehicles associated with job duties and must pass a DOT physical. Must be able to obtain and retain a License (CDL) with proper endorsements to operate all applicable Company equipment; or if a current CDL holder, license must be in good standing.

- Thursday, March 04, 2021

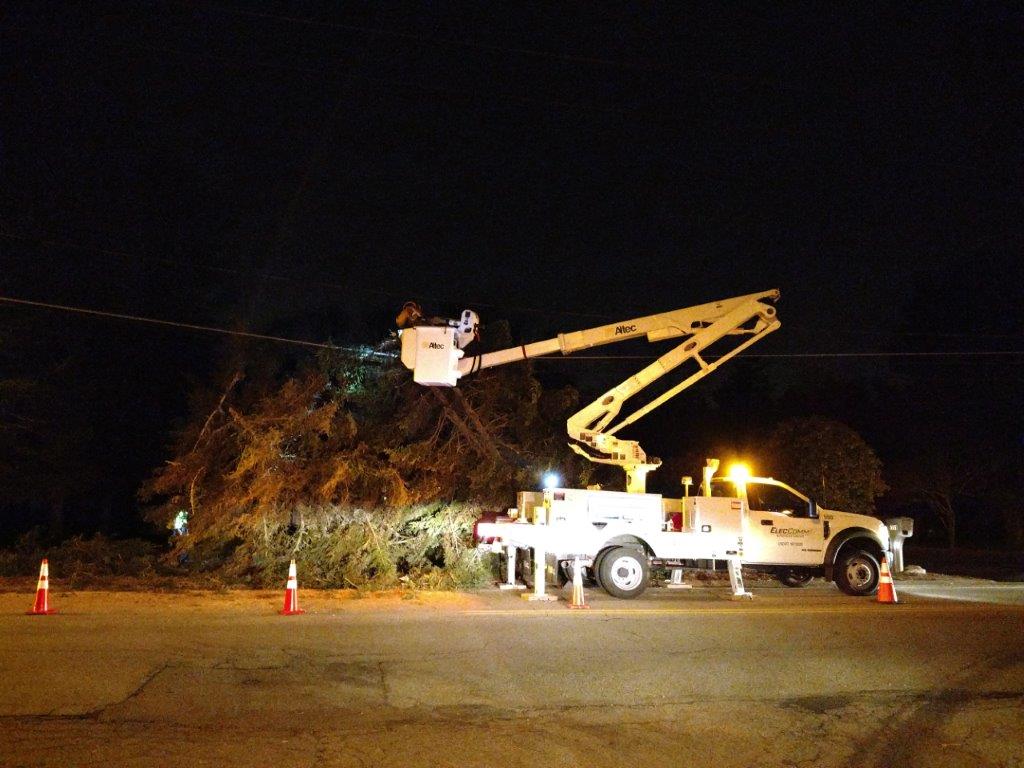

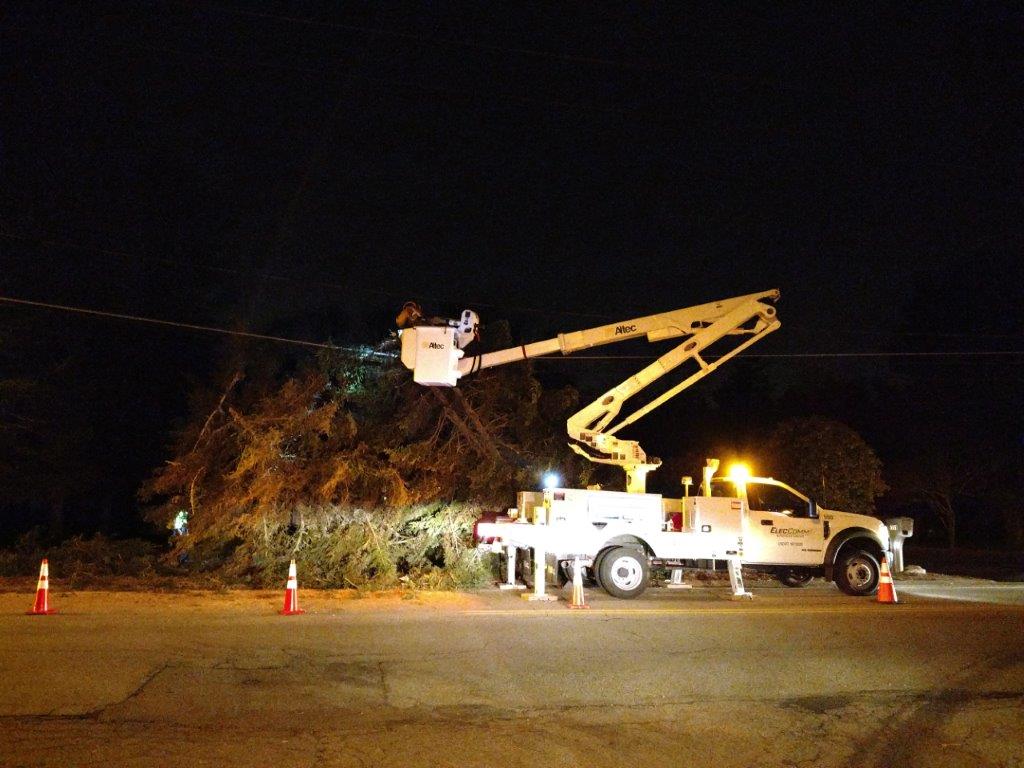

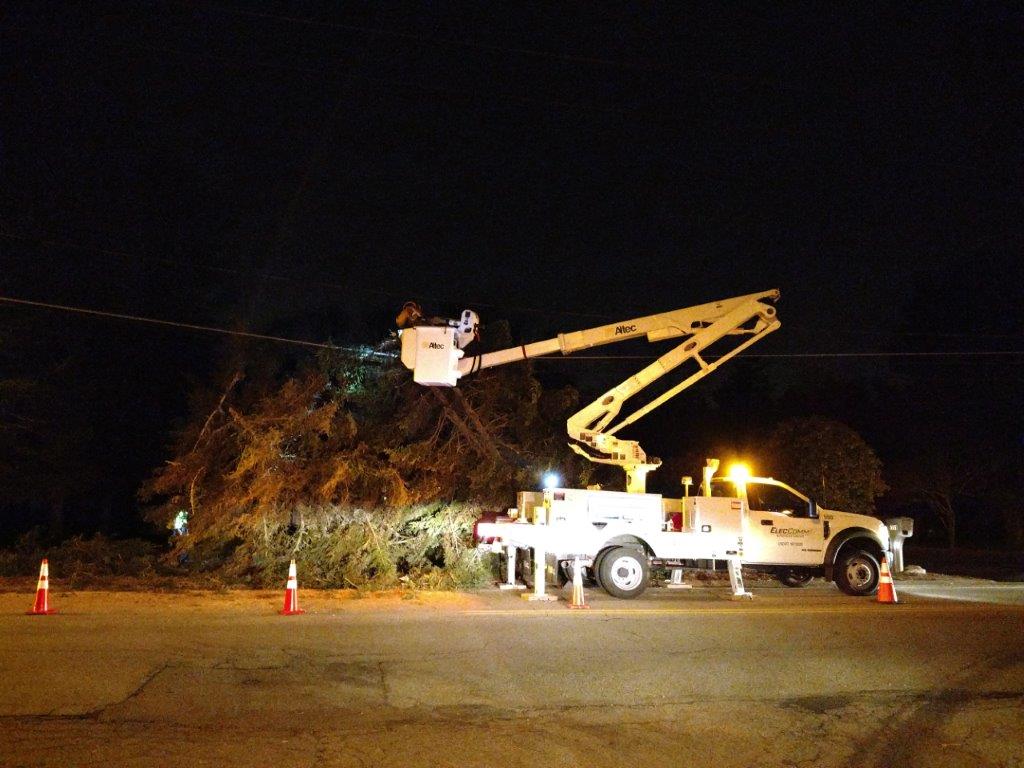

When your customers are in the dark due to storm, trees, vehicles, or whatever other threats loom out there, know that you can restore services and solidify your reputation via contract rapid response electrical restoration services. Emergency power restoration is a an ElecComm core competency that time and time again proves effective and appreciated by power companies all across New England.

In facing the aftermath of a storm, it goes without saying that you understand the challenges regarding downed towers, damaged transformer stations, snapped poles, and countless other causes of outage. We certainly do because we’ve responded to these outages for years now. By many power providers, we are considered their single most valued partner in business. And we’d welcome the opportunity to be yours.

Contact ElecComm in the event of power emergencies across New England.

- Monday, March 01, 2021

ElecComm continually looks to add new experienced or entry level talent to our expanding workforce. Our team is distributed throughout New England and we encourage applicants from surrounding states. ECC is a UWUA local 369 company.

ECC takes pride in our team and offers a well-rounded benefits package that includes comprehensive medical and dental coverage, a 401(k) plan with company match, profit sharing plan, life and disability insurance as well as paid time off.

We pride ourselves in safety, health, training and state of the art equipment for our employees and participate in the UWUA Apprenticeship Program. Our team is continually cross trained and upholds the highest safety standards in the workplace. ECC is an equal opportunity employer.

Please submit your resume to info@eleccommc.com

Employment Opportunities:

- UG Lineworker Leader

Responsible for the installing, and constructing of plant and equipment. Directs and trains employees of an equal or lower rating. Incubmbents work under general supervision. More info...

- UG Lineworker Class 1

Responsible for the installing, and constructing of plant and equipment. Directs and trains employees of an equal or lower rating. Works under general supervision. More info...

- UG Lineworker Class 2

Responsible for the installing, and constructing of plant and equipment. Directs and trains employees of an equal or lower rating. Works under general supervision. More info...

- UG Lineworker Class 3

Responsible for the installing, and constructing of plant and equipment. Works under general supervision. Works under directive supervision when installing cable or equipment.More info...

- Thursday, February 25, 2021

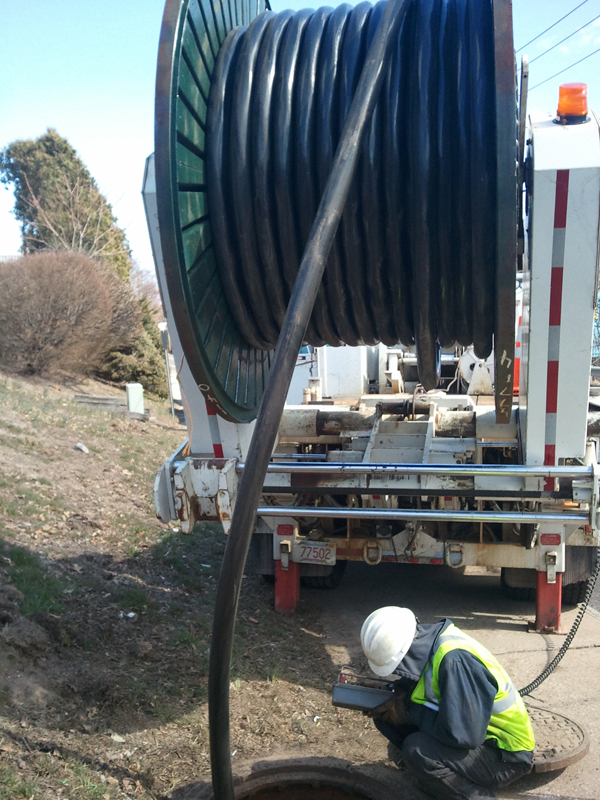

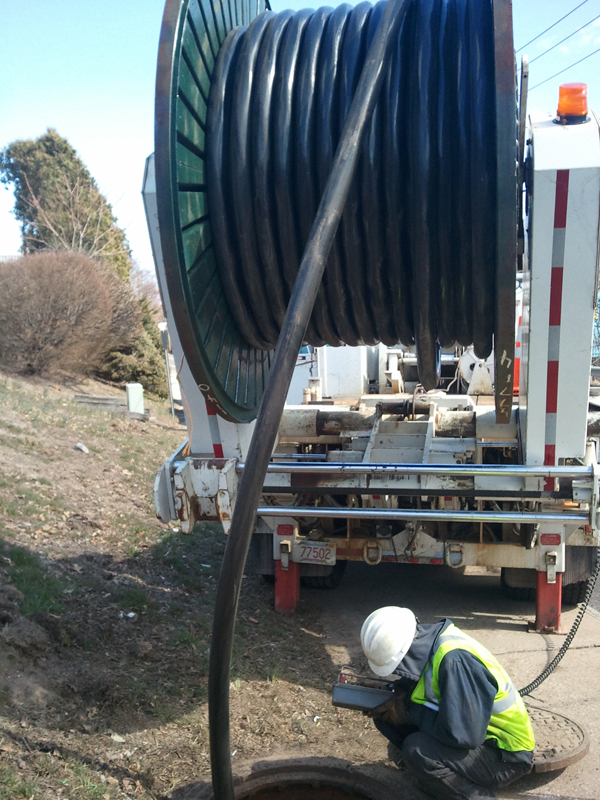

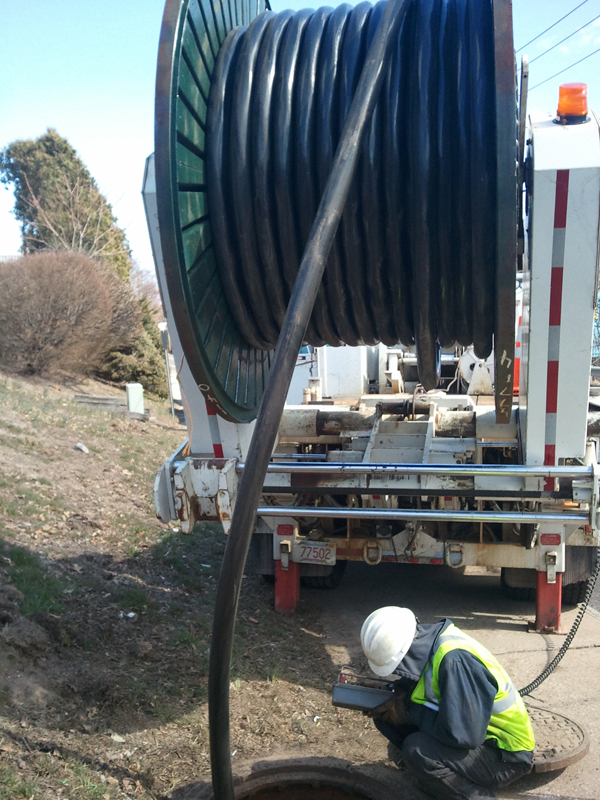

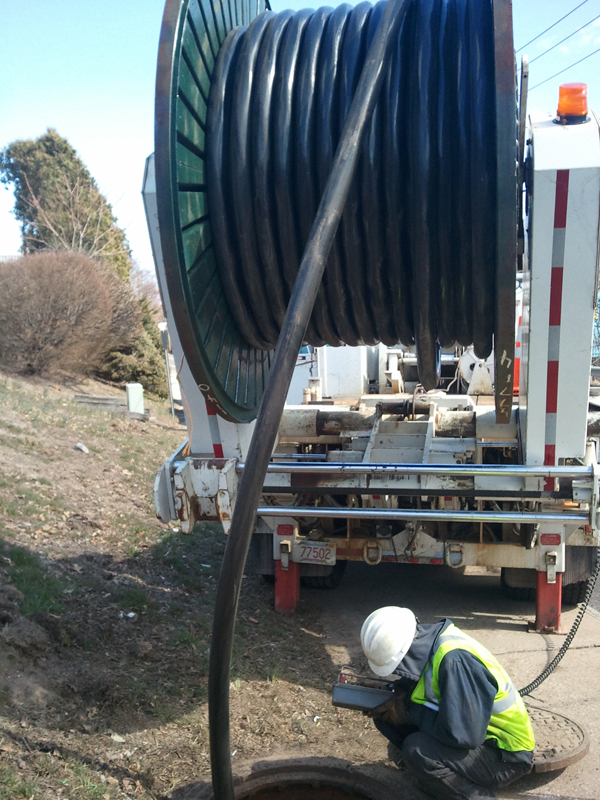

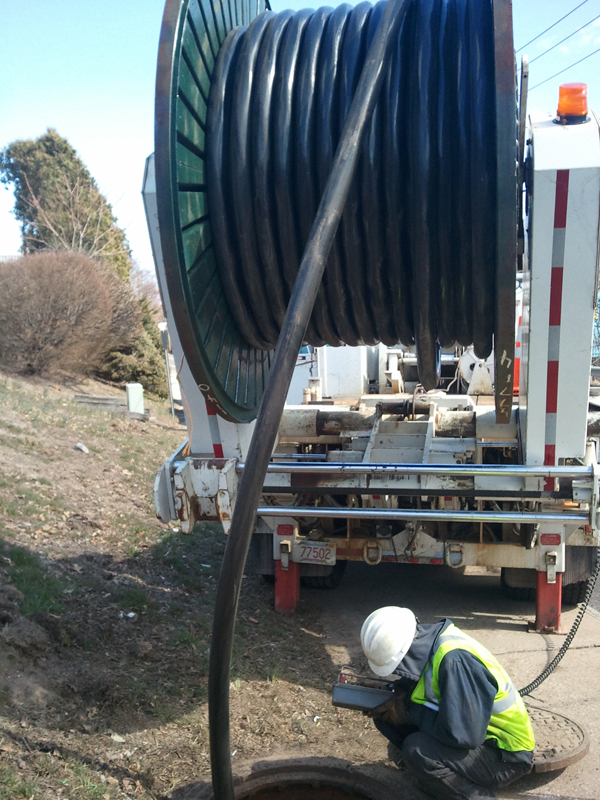

Installing, maintaining, and repairing underground electrical cable systems requires highly trained and experienced technicians. This is not a simple task. All activities must be coordinated with procedural definitions clearly communicated to attain safe and effective exposure to underground electrical cable systems. We make this happen for all entities charged with underground cable system operations.

Before starting the job it is important that all information related to work in process will be disseminated to the concerned parties in order to have an access to locked areas and basements. Delay will be avoided once the materials are delivered on site and an ocular inspection at the site is highly important in order to check the area and make sure no other parties will be working in the area once you commence work. It is necessary to ensure the conduits are marked to provide instructions to the certified electrician to install the strings. More so, the rack locations need to be set up a little distance from where you work. Avoid getting too close to the point.

And to ensure safety in using the cables, identify the cable by putting a label on each cable and add a pull string to each pull. And when you are about to pull, replace all the pull strings with a rope. In this way, all cables are easily identified and will not get stuck. Nothing beats complying with all the safety precautions that will give a successful cable pull.

If you are looking for expert technicians to safely perform an underground cable installation project, contact ElecComm.

- Thursday, February 18, 2021

Prompt, proven, professional, reliable, and affordable electrical power storm response services are attainable right here in Boston. Of course, you can’t predict when mother nature will deal us another crushing blow, but we’ve restored Boston-area power for years now and want to team with you in advance of the next storm. Your customers demand prompt response and ElecComm’s electrical power emergency storm response team will deliver that for you.

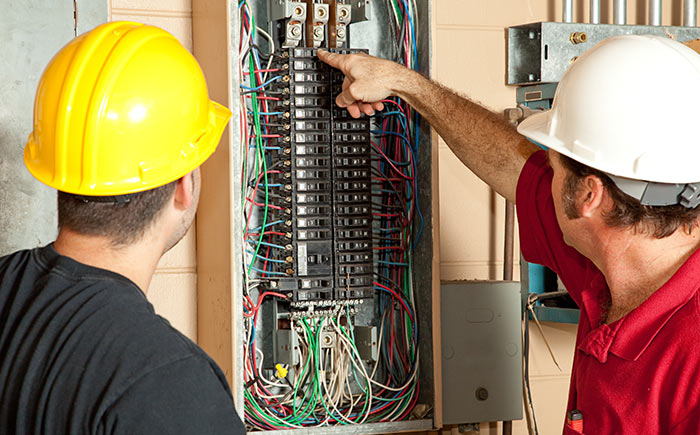

During winter, technical glitches and storm-related destruction of overhead powerlines is inevitable. Snow, wind, ice, and vehicle impact dismantle the flow of overhead high voltage power systems. Repair and maintenance to overhead power lines is routinely outsourced to the trusted professionals here at ElecComm. Our crew is made of expert electricians who have the knowledge and skills, as well as the relevant experience to ensure that power is restored as soon as possible. As a result, homeowners and businesses will be unnecessarily inconvenienced from the unexpected loss of power in storm-damaged areas.

The crew at ElecComm is dispatched to the location of downed power lines to conduct immediate and accurate repairs. When large-scale power outages occur at the same time, our crew will focus on the areas where the primary lines are down in order to immediately put an end to the inconvenience that such downtime causes to homeowners and businesses.

To find out more about repair and maintenance to overhead power lines, contact ElecComm.

- Thursday, February 11, 2021

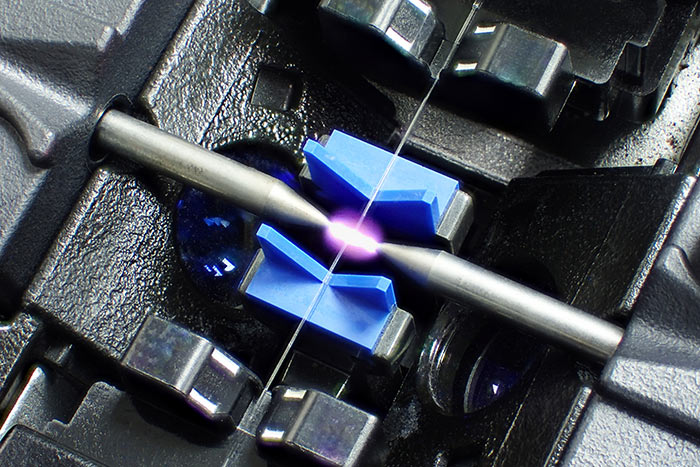

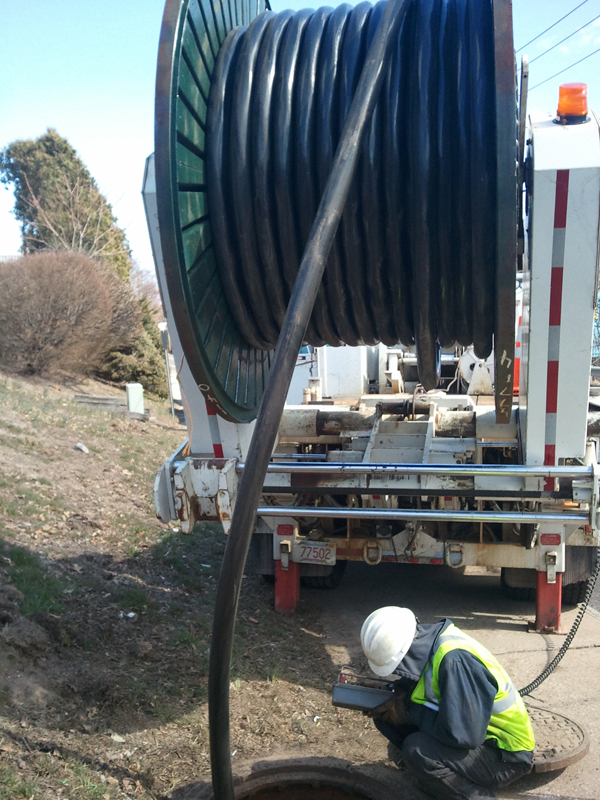

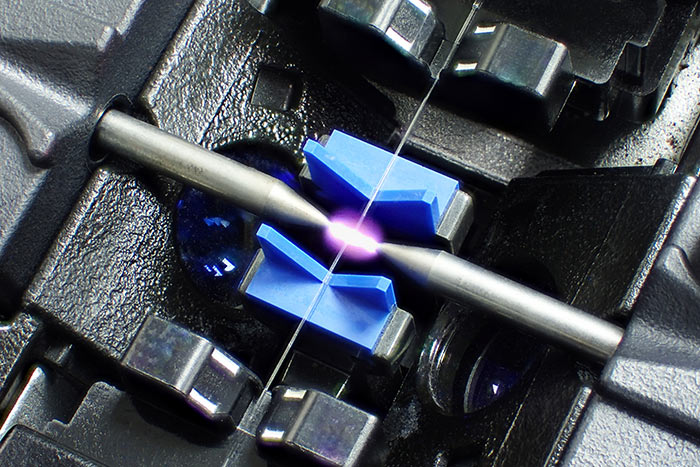

Fusion splicing is increasingly popular for fiber optic termination. This is because of the process delivers excellent performance benefit while simultaneously providing protection against cable failure and weak signals. The result of which is the effective joining of two optical fibers end-to-end makes the light passing through the fibers intact and reflected back by the splice.

The process of fusion splicing is done with the coatings removed and the two bare fiber ends are fused together by heating with a high-voltage electric discharge. After heating them for a short time, the surface melts and pushes together until both ends are brought in close contact with a small gap in between. The pressure is in achieving a good alignment between the two fiber ends. In order to be precisely aligned the fibers before the splicing are ensured that the core matches well. It is to avoid the risk that the surface tension will pull the fiber ends towards a position other than the areas that have been matched.

The fibers ends are normally prepared, split off and placed in alignment fixtures on the fusion splicer. The fusion splicer is the machine used to weld or fuse two optical fibers together. And to ensure utmost safety protection of the heated shrink splice sleeves is to store correctly in a proper storage that has ideal condition against moisture and other environmental hazards. By doing so, it will maintain its effectiveness and secure the fragile joints.

For more tips on Fusion splicing, contact ElecComm.

- Thursday, February 04, 2021

Smart planning in restoring power after a natural disaster or any unexpected disaster is vitally important. It is necessary to have an advance contingency plan for this kind of unforeseen disaster. Electrical emergency plans will cover and easier implement once everything has been put in place. Do not get caught unprepared before any worse happens.

A contingency plan for continued operation in the event of any weather emergency is extremely important. Immediate actions taken during the first 48 hours of a disaster are highly critical in determining the recovery of any business. It is strictly part of the security regulation that facilities personnel will prepare emergency plans for a potential situation. Efficient and quick restoration of power after the disaster will be faster and easier once the electrical equipment is ensured and are properly maintained. Always remember that developing a safety program that incorporates the emergency procedures will be very helpful and beneficial. It is a safety procedure that everyone in the facilities is aware of the most current natural disaster recovery codes and standards in order to easily implement when the need arises.

Power outages are expected in the entire system after any calamity. As such the most important factor of disaster preparation is developing an electrical emergency action plan (EEAP). Creating this plan will safely and efficiently restore operations. Having an EEAP on site, the facility personnel will understand the significance of electrical assets, analyze the critical operation infrastructure and electrical risks to be avoided that will allow an immediate power restoration operation.

For more tips on power restoration, contact ElecComm.

- Sunday, January 31, 2021

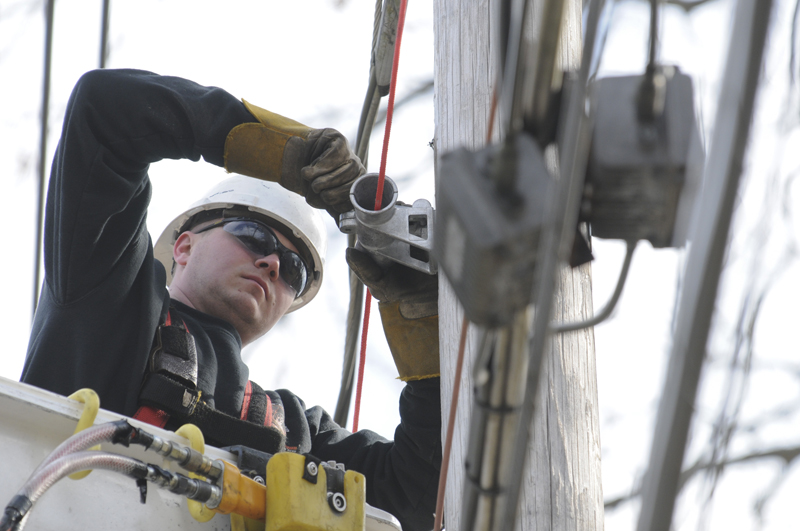

In transmitting electric energy especially for long-distance transmission to large quantities of electric energy, overhead power lines are the most commonly used. This is because the uninsulated electrical cables being suspended in towers or poles are insulated by the surrounding air as it is in an open space. And once the safety measures and required overhead line standards are followed, it provides greater comfort and improved functions in the distribution of electric energy without interruptions.

The efficiency of an overhead power supply in transmitting or distributing electric power depends on the design of the line. Overhead power lines must possess the mechanical strength to survive various weather conditions. With that said, sometimes mother nature is just too strong. High winds, falling trees, salt, and other elements conspire to destroy the continuity of the line. When that happens, ElecComm is equipped, trained, and ready to respond.

When power disaster strikes, turn to professionals of ElecComm’s Power Emergency Response Team.

- Thursday, January 28, 2021

Today we’re going to address the vital importance in applying fireproof coating to all high-voltage underground cabling systems.

This is especially true at coal-fired power plants. In almost every underground high-voltage cable run at coal plants, the cable will be exposed to varying degree of coal dust. It is vital to not only remove this combustible dust but to protect the cable should any of the dust ignite. As such, cleaning the cables is a big task before the coating is done. It is also an essential requirement that the fire security teams are knowledgeable and experienced in coating applications. With the expertise of the fire security teams, the repair of high voltage cables without any shutdown of production is highly commendable. Normally, replacing damaged cables requires a shutdown of operation. Likewise, the fire protection of the cables reduces the company's operational cost in insurance and other related matters.

The fireproofing works that render something fire-resistant or incombustible to an entire structure or some building components is a compliant fire protection measure that increases electrical safety in the underground construction.

For more tips on electrical fireproofing, contact ElecComm.

- Thursday, January 21, 2021

Downed power lines are a certain and dangerous winter threat. Power disruption takes a second-seat to safety in the early stages of power line failures. Rapid response to the situation is key. ElecComm’s storm response team exists to safely resolve such issues safely and fast!

You may sustain severe to fatal injuries by touching- or being too close to- power lines. So ElecComm wants to remind you again about safety tips to prepare in the event you encounter a downed electric power line.

- Assume all downed cables as live lines. Stay at least 35 feet away. Electricity can travel through water and the ground around power lines.

- Report any downed wires to the local authorities or electric company right away. Stay far back.

- Refrain from clearing snow, ice, or storm debris until the power is disconnected or power lines are repaired.

- If a power line lands on your vehicle while you are in it, stay in the vehicle until emergency responders arrive. Exiting a vehicle that has been contacted by a live power line is extremely dangerous. Similarly, do not attempt to assist someone if their vehicle is in contact with power lines.

- If you notice the power line is on your vehicle before you enter, stay out of the vehicle, back away, and call the authorities and/or the local utility company.

For prompt emergency response and rapid power restoration, contact ElecComm.

- Thursday, January 14, 2021

For many businesses across the greater Boston area, reliable and fast network infrastructure is fundamentally important to remaining competitive. For years now, Boston business owners have entrusted their telecommunication network installation and maintenance services to us here at ElecComm. We understand the criticality of this service to your business and we work with professional speed, effectiveness, and affordability that will earn your trust.

Every business’ network is custom and strategically engineered to your exact business communication strategy and need. We employ state of the art network electronic and physical security measures to protect your intellectual capital to the maximum extent possible. Like most business across Boston, yours is likely composed of cross-functional teams, therefore we’ll design your telecommunication network to facilitate and integrate your teams smartly. Telephones, internet-connected computers, fax machines, servers, and handheld mobile devices are more useful because their capabilities are increased through a carefully developed telecommunications network. Fiber optic networks provide an effective platform to actualize joint ventures to improve team output and customer service.

To find out more about fast, reliable, and affordable telecommunication network services, contact ElecComm.

- Thursday, December 31, 2020

For years now, whenever emergency power situation arise across the greater Boston area, EleComm has proven ready and effective in getting things solved. We’ve developed a team of electrical professionals, all equipped with state of the art electrical repair equipment, to restore power at the most value priced service available across the area. It is a badge of honor that we all wear knowing that we restore critical services on a regular basis to our friends and neighbors here in Boston.

The emergency restoration of electric power normally undergoes a series of restoration activities. There are some factors for consideration like the extent of damage to the electrical system and the specific location in which to perform the emergency process. Another factor is the availability of the workers or personnel who will conduct the repairs and their technical know-how. Adding more, it is the priority to give immediate repair on the critical situation of the load and goes with the availability of equipment and facilities to complete the required repairs. After careful assessment of the situation, only then the immediate repair will be carried out.

There are organizations that specialize on the restoration process which provides efficient and professional electricity system operators that have undergone testing and licensure on their knowledge on distribution, transmission and other utilities that have supported credentials based on their skills and the resources of the line and electrician crews issued by the local utilities. And with this, a trusted and reliable repair system is promptly undertaken and restored.

For more tips on Emergency restoration, contact ElecComm.

- Monday, December 21, 2020

Warm Holiday greetings to you all. We write this note to you with joyous confidence that 2021 will bring happier, healthy, and more profitable days to us all! That wish is certainly a cause for optimistic celebration this Holiday season.

Our Holiday gift to you is the gift of small business in your community. To be able to buy locally is a true gift to your neighborhood as well as to your family and friends. We hope that everyone reading this takes a measured effort to buy local to the fullest extent possible, not only during this Holiday season but going forward as well.

Buying local is one of the best gifts you can give to your neighbors and your community. Visit a local restaurant, salon, store, or shop for better relationships and better customer service; but more so you can shake the owner’s hand and wish them the best in 2021 and beyond. That will be a gift for you both. Help make this a joyous holiday for everyone: Give the gift of your business to a local business.

We wish you and your entire family happiness, health, and warmth this Holiday season. Our warmest regards to you all.

- Monday, December 14, 2020

When active in fiber optic install and maintenance support there are safety precautions that must be followed. Today we discuss safety precautions to take to protect eyes.

In the fiber optic work arena it is critical that everyone entering inside the area wears safety glasses with side shields. This is especially true when accomplishing splicing or termination activities. Worker’s eyes are susceptible to injury from transmission of light. Anyone looking directly at the transmission of fiber optic light frequencies can suffer the loss of visual acuity or blind spots. More so, the fiber fragments are a very serious hazard since they are very small pieces of glass such when small fragments fall, it is very hard to be seen and need to be picked up with tweezers hence it is advised to use a dark mat that is chemical-resistant and elastic on the work surface. Lastly, all food and beverages are strongly prohibited to be entered inside the work area.

And in order to ensure safety in the workplace, when finished with a fiber optic job, all cut fiber pieces will be disposed of properly along with any used chemicals and containers. And employees leaving the work area are required to check their clothing for pieces of stray fiber and in case they find something, it will be removed with double-sided tape. Overall, once work is completed it will be necessary to follow the safety rules that will keep the workers healthy and the work environment safe for all employees as a whole.

For more tips on Fiber Optic, contact ElecComm.

- Monday, December 07, 2020

We are proud of our reputation here in Boston for being THE go-to company for emergency above ground power line repair and restoration services. We specialize in rapid response power restoration, but we specialize also in a host of other electrical-related services. But we do so much more than that. Let’s discuss two other services that Boston-area business owners benefit from:

Underground High/Low Voltage Cable Installation and Removal:

All cable sizes including, not limited to: 1000Kcml, 700, 500, 300, 250, 1/0, and 2str.

- Copper or Aluminum Cable

- URD Installations

- Rod/Rope and brush ducts

- Pump and Clean MH's

- Fiber Optic and Cable Installation and Splicing

- Inner Duct Installation

- All Grounding

Telecommunication Network Solutions

We engineer, manage, and perform network construction, splicing, testing, and restoration services for fiber, copper, and hybrid fiber-coax telecommunications networks.

For more information on our wide-range of electrical services to include rapid response overhead repair services, contact ElecComm.

- Wednesday, November 25, 2020

We have all been challenged this year. But, never have we felt closer to our family, staff, customers, and vendors. For this we can give Thanks. The Covid-19 pandemic challenged our business as it did each and every business across our great nation. But, we would like to share with you the positives that came out of this experience.

Our families, our staff, our customers, and our vendors all remind us of the blessing it is to own and operate. The support that you have all provided, and continue to provide, during one of the most troubling and challenging times in American history is nothing short of humbling. That we in our own way returned some of that support to you has us arriving this Thanksgiving season with a deeper appreciation for our relationship with you. We move forward with an extraordinary focus to ensure that the quality of our service meets your needs, expectations, and earns your continued and highly valued trust. We do this with confidence that, together, we all will make it through the unique challenges that lay ahead.

In many ways we have more to be thankful for this year than ever before. This Thanksgiving season, we continue to reflect, recognize, give thanks, and be warmed by you all. As always, we invite you to contact us anytime with ideas, questions, and/or concerns. Thank you, and sincere "Happy Thanksgiving" wishes to you all!

- Thursday, November 19, 2020

The winter snow is beautiful. Families love it for good reason. But electrical utility providers know that snow turns to ice, ice is heavy, and ultimately wreak havoc on overhead power utility lines. We exist to rapidly respond to power emergencies.

Here are some of the various ElecComm power restoration assets that are prepared, checked, and ready to rapidly respond to any emergency:

- Man-lift Bucket Trucks

- Material Bucket Trucks

- Cable Truck

- Cable Load Lugger

- Digger Derrick

- Underground Cable Puller

- Splice vans(Step Van)

- Aerial Splice Van

- Cable Trailer(heavy duty)

- Cable Trailer(light duty)

- Cable Pulling Machine

- Fiber Optic Trailer

- Generators(Hydraulic)

- Fiber Optic Pulling Machines

- Fiber Cube Van

- Pick-up Trucks

- Rod/Puller

In the event of technical glitches in the power poles due to strong wind and fallen trees, don't hesitate to contact ElecComm. Our team is always ready to respond 24/7.

- Thursday, November 12, 2020

ElecComm team is prepared and ready for the damaging Boston winter weather that wreaks havoc on the regional electrical grid. Winter power outages are increasingly common in Massachusetts, New Hampshire, and the rest of New England. Once again, we’re geared-up and ready to rapidly respond to any interruption within the commercial power grid system. Bookmark this link to our electrical emergency storm response team.

As you know, power outages negatively affect residents and businesses alike. Numerous critical services are disabled to include some life-sustaining medical equipment that has limited or no emergency backup battery capability. Time is of the essence for repair of any power disruption, and we run away from all electrical repair companies in terms of rapid and quality electrical power problem resolution services. The ElecComm power emergency response team remains on standby 24/7 and ready to respond on moments notice. We serve public and private utility companies as well as private businesses across Boston and the entire New England region. For more information on storm response and power restoration, contact us.

- Thursday, November 05, 2020

As the demand for electric power grows in Massachusetts, distributors are developing high voltage cable networks that are faster and more efficient. Overhead power lines have always been the preferred choice because of their affordable cost. However, in terms of performance and environmental acceptance, underground power lines are a more favorable alternative.

Underground high voltage cable networks here in Boston are the preferred solutions for new power distribution needs for a host of reasons. Since the cables are located below the ground, the entire system is shielded from environmental and man-made stressors that take down overhead power solutions. No power system is completely risk free. With that said, it is easy to understand the toll that severe Boston winter weather and downed trees alone have on unprotected above-ground power lines. That same harsh winter places a comparatively harsh corrosion burden upon above ground lines while the buried cable network is largely protected from the same.

Underground high voltage cable installations here in Boston offer additional advantages for power distributors. An underground network of high voltage cables is faster to install and offer a large degree of beautification to the Boston skyline. These cables are strategically engineered to minimize energy loss, improve transmission reliability, and reduce risk of network failure.

To find out more about the advantages and applications for underground cable networks, contact ElecComm.

- Thursday, October 29, 2020

A successful cable pulling experience is achieved once proper planning is being worked out correctly. With the use of the proper tools and necessary thorough preparation, the actual process will save time and yields optimum productivity in the job site. A little anticipation or creative thinking on the work to be done will save the cost of doing the re-pulling cable runs that will be damaged during the initial installation.

There are different factors to be considered in the pre-planning stage before the actual cable pulling is done. Before starting work on the job site, installers or technicians will identify the type of environment. It is a common mistake to pull cable when it has been stored in a cold environment. In this case, the insulation will be affected and is conducive to cracking or splitting even with minimal pulling tension. Hence, damaged insulation is like compared to no insulation at all in the future. Adding more the moisture will affect the cables than others. It will affect the insulation and capability of the cable. Whatever the cable type is, it is of utmost importance to seal the cable ends with an approved sealing method.

A productive cable installation will require essential knowledge and understanding on the basics of cable. It is highly important to identify the cable type and specification, the temperature, checking the moisture, set up the cable route and the necessary hardware for cable support. In addition, the proper scheduling of multiple cable runs to be pulled at one time will reduce labor costs and only then it is assumed that the cable pulling will be successful.

For more tips on telecommunication network installation, contact ElecComm.

- Thursday, October 22, 2020

Empowering Boston-area business owners with safe, secure, and reliable data transmission is the sole focus of our telecommunication network team here in Boston, MA. Here’s a quick reference to the specialized network installation services provided here by your team of ElecComm professionals:

- Engineering

- Project Management

- Site Survey

- Installation of fiber plant including (ISP) Inside Plant and (OSP)Outside Plant all aspects

- Installation of FDP(Fiber Distribution Panel), Wall Box splice boxes

- Installation of OSP splice enclosures including aerial enclosures pedestals

- Installation of network center and fiber hub equipment

- Deployment of CWDM and PON network

- Deployment of 10gig network

- Deployment of FTTT network

- Deployment of FTTH and cell backhaul network

- Deployment of Municipal networks

- Deployment of Metro fiber rings

- Deployment of Utility/Smart Grid networks

We provide a host of other telecommunication network services that we welcome the opportunity to discuss with you personally. Those service include (but are not limited to):

- Underground Network Construction

- Overhead Network Construction

- Fiber Splicing

- Network Installation

- Scheduled Maintenance

- Emergency Restoration

Teaming with a proven telecommunication network support provider is a profitable business endeavor. Team with us. Contact ElecComm.

- Thursday, October 15, 2020

Electrical system support provider’s worst enemy is winter weather. The end users of your power systems count on uninterrupted power. In areas primarily supported by overhead power lines, this is an unrealistic expectation. Rapid-response problem resolution is expected and will largely drive the reputation of the electrical support provider. That’s when ElecComm’s Storm Response Team” becomes Boston-area’s electrical service provider’s best friend.

We encourage any and all of you to get ahead of the game and establish a relationship with our Storm Response Team. You need to know exactly how well we are equipped, staffed, and our reputation for minimizing the time required for emergency electrical repair across Boston. So when your systems go down, we’ll deliver upon your expectation management as we have for all our Boston-area customers for years now.

But just to be clear, we are so much more than an electrical emergency response force. We constantly repair and replace aging electrical infrastructure. In fact, we have an entire division dedicated to underground high/low voltage cable installation, removal, and repair.

We are the region’s most trusted electric and communications line construction company. We forge strategic partnerships that not only limit the impact of weather emergencies but empower you with dependable and value-bases services that improve our client’s reputation and profitability.

Know that ElecComm is always ready to respond to your electrical power system upgrades and maintenance needs. Contact ElecComm.

- Thursday, October 08, 2020

Today we focus on the high voltage consultation side of our business services. We’ve delivered underground cable repair and maintenance services across Boston for years now. But our focus is first and foremost about the safe execution of high voltage cable operations. So let’s talk high voltage safety for a moment.

A strong high voltage operations and safety record does not come by accident. Strong attention to detail is required to achieve this result. It is of extreme importance to prevent accidents from underground services. Severe injuries or fatal damages are avoided when you take specialized care to avoid damaging underground cables. Strict compliance of the Home, Safety and Environment rules (HSE), while seemingly overly constrictive, provide the necessary constraints regarding digging near underground cables that protect equipment and personnel alike.

High voltage service operations demand the use of heavy and powerful machinery that can and do crush cables. If the cable is hot, this leads to explosion, flame, and exposure to high energy. This often results in severe burns to hands, face, and body even if protective clothing is being worn. Worst scenario people will be injured or killed by electric shock. Detailed advanced planning must be accomplished before ground is broke. Detailed excavation and line addressment planning is a core competency of the professions here at ElecComm.

Before you dig, allow us the privilege to develop and execute your high voltage operations plan. We’re confident no entity can do this for you more effectively and at the value pricing offered by us here at ElecComm. To get started, contact ElecComm.

- Wednesday, September 30, 2020

For years now, ElecComm has served as Boston’s electrical repair emergency response team. The brutal Boston weather produces high winds that knock over trees and any power line in the near vicinity. Even on the calmest winter weather (that will soon arrive us), snow and ice send branches tumbling and onto power lines. We’re proud of the fact that over the years, we’ve promptly responded to power emergencies across Boston to return power to both public and private entities, often times, in a lifesaving manner.

Another issue with extreme temperatures is that consumer demand for energy is higher. Heat pumps are operating continuously, emergency heat systems and electric space heaters are running as well. If temperature extremes are worse than forecast and/or happen faster than forecast, the utility providers may not have planned for or had enough time to bring sufficient generation online to support the demand. This can result in local or widespread overloads that may cause service to some neighborhoods to go offline automatically or switch to rotating blackouts. We’ve seen it all and we’ve been a trusted source to solve Boston power emergencies. For more information on power line emergency response or infrastructure repair and/or electrical augmentation services, contact ElecComm.

- Thursday, September 24, 2020

Overhead and underground electrical cables require periodic maintenance to maximize their functional reliability and lifespan. If you manage underground power cable systems in or around Boston, ElecComm is your trusted source for line maintenance services.

Buried electrical wires are susceptible to faults caused by nature (water, dirt), failure of molded joints in splices, and of course the all too often break during excavation. Locating the underground cable faults can be an impossible task for anyone but seasoned electrical line professionals. The repairs can be both challenging and time-consuming but when armed with the latest in fault-locating technologies, this process is streamlined and affordably executed. We verify and optimize the integrity and condition of ground connections, cable joints, and splices to eliminate threats to service continuity.

In any power distribution system, proper preventative maintenance is crucial and an often overlooked necessity. Our core competency is power distribution systems empowers you to operate with confidence that disruption of electrical line service can be a thing of the past for anything other than an errant back hoe cut. Contact ElecComm to get things started.

- Thursday, September 17, 2020

ElecComm has delivered underground high and low voltage cable installation, upgrade, and maintenance services across the greater Boston area for years now. The installation of underground high voltage cable offers multiple benefits. Municipality managers dramatically improve the appearance of their local by eliminating poles and overhead wires. More importantly, though, it improves the reliability and safety of your city’s electrical system.

ElecComm's core business focus is on the installation, removal and maintenance of overhead and underground electric/communications distribution systems. We install and service all cable sizes including, not limited to: 1000Kcml, 700, 500, 300, 250, 1/0, and 2str. Here’s a list of some of the specific services that we deliver to public and private enterprises across Boston:

- Copper or Aluminum Cable

- URD Installations

- Rod/Rope and brush ducts

- Pump and Clean MH's

- Fiber Optic and Cable Installation and Splicing

- Inner Duct Installation

- All Grounding

In harsh weather climates like Boston, underground power lines offer a cost-effective solution for improved power reliability and safety. We specialize in this area. Contact ElecComm anytime.

- Monday, September 07, 2020

Fiber optic network support services, like what we provide across the greater Boston area, provides data integrity backed by years of technical excellence. Businesses across Boston are switching and upgrading to Fiber optic networks at a pace like never before and ElecComm is leading the way.

Fiber-optic networks are faster, more reliable, and more durable compared to their counterparts and provide continuous, high-speed connectivity needed in today’s business operations. Further, as a short overview of how it works, Fiber optic cables consist of bundles of narrow, long strands of glass that transmit light over long distances. The process is called a total internal reflection in which the light bounces along the walls of the cable core, which are lined with mirrors. Because the speed of light is fast, the speed of fiber optic networks is fast too.

We install, repair, and maintain fiber optic networks as a core competency of our business. Your data networks are something to be very selectively entrusted. We are Boston’s selectively entrusted fiber optic network professionals. Let us go to work for you. Contact ElecComm.

- Friday, August 28, 2020

Most of you realize that ElecComm provides Boston business with a wide-range of electrical support services. This includes any number of emergency power support solutions from simple on-site power outages to natural disaster storm response. Today, let’s focus on the on-site power emergencies and how you and we work together to resolve.

When a power emergency strikes a business or project site, it is common for panic to be the first instinctual reaction. In order to keep all safe and to rapidly return to normal business operations, having an electrical contingency response plan in place is fundamentally important. That’s where we come in.

In any project or construction sites, there is always the potential of electrocution and/or electrical fire danger. These issues are more common than you might think. With careful planning and preparation, the threat of these thing are dramatically reduced. It is of utmost importance to comply with proper safety measures and proper training that will greatly prevent electrical fires and accidents. Providing up-to-date training and supervision to all workers will significantly prevent dangers especially those working directly with electricity. Strict instructions and compliance with employees will help in knowing how they handle themselves around high voltage equipment.

We can help both prevent and respond to electrical emergencies. Take a quick look at how we provide electrical safety training to our own staff.

For more information electrical emergency response services, contact ElecComm.

- Friday, August 21, 2020

Electricity is an essential commodity that we pay less attention to until our lights go out. Since electricity plays a major role in our day to day activities, people depend on electric companies to ensure a continuous stream of power. While electric companies are constantly improving their ways to respond promptly to emergency situations, however natural disasters are beyond our control.

Overhead power lines are prone to significant damage. Strong winds can knock down trees and possibly snap power cables causing widespread outages. In these unfortunate events, electric companies should respond promptly to restore power at once. ElecComm storm response team are trusted partners of major power utility companies and commercial industries across the New England region. Moreover, our services now include daily and preventive maintenance of electrical poles and lines. These operations are integral preventative measures to somehow mitigate the impact of the disaster, especially to the commercial sector.

If you need immediate electrical assistance during the storm, contact ElecComm. Our team are 24/7 ready to respond to any emergency power restoration, electrical system installation, or electrical infrastructure maintenance needs.

Joseph Coupal - Thursday, August 13, 2020

In any and all Boston-area commercial enterprise, privacy and protection of corporate data is both crucial and governmentally mandated. With your data networks under constant attack, attacks that directly threaten your intellectual property and your user privacy, the threat to your business continuity, your intellectual property, your employee’s data, and your reputation are all things that warrant a comprehensive data strategy. If you and your business have not fully converted to a full Fiber-optic communication network backbone, it is beyond time to do so. Fiber optic network transmission is simply the most secure and reliable network option available today.

With the recent technology Fiber optics using the updated cryptography where a smallest possible discrete unit is being used to transmit multiple data streams at the same time in different colors of light. As such the data leakage becomes lower and reduces tremendously. Since using a network people and businesses efficiently communicate with groups of people through instant messaging, video conferencing, social media, chat rooms, etc., and it is the best way and easier to share files, data, and information. It is due to the Fiber-optic internet that works in the fastest and most reliable current internet invention available. With its amazing connection, speed, and reliability, it builds and works for a better and effective connection with clients and people around the world.

Fiber-optic communication elevates the business’ integrity and client trust which are the two most important core values in an organization. With the enormous benefit of Fiber optic, many internet providers have achieved their economic peak through the increasing demand of companies and individuals wanting to utilize this great technology. Overall Fiber-optic communication certainly contributes to the strengthening of the world’s internet economic efficiency.

To learn more about Fiber-optics telecommunication network, contact ElecComm.

Joseph Coupal - Friday, August 07, 2020

We provide a full range of underground and aboveground electrical cabling services across the greater Boston area. Since electrical line safety is (and always will be) a foundational focus of our services, we thought we’d share with you some thoughts regarding “overcurrent” conditions that we discover that create very dangerous conditions that must be rooted out.

First, the basic concept of overcurrent relates to an electrical line transporting current beyond the current rating of the equipment. Complying with the precautionary measures in any < a href="http://www.eleccommc.com/hvoltage.htm">electrical system keeps people safe and thwarts off system failure. Maintaining the electrical system’s per manufacturer’s instructions keep the systems in good and safe working conditions. We are routinely hired by Boston-area electrical system managers to ensure their systems operate safely, within specs, and at peak efficiency.

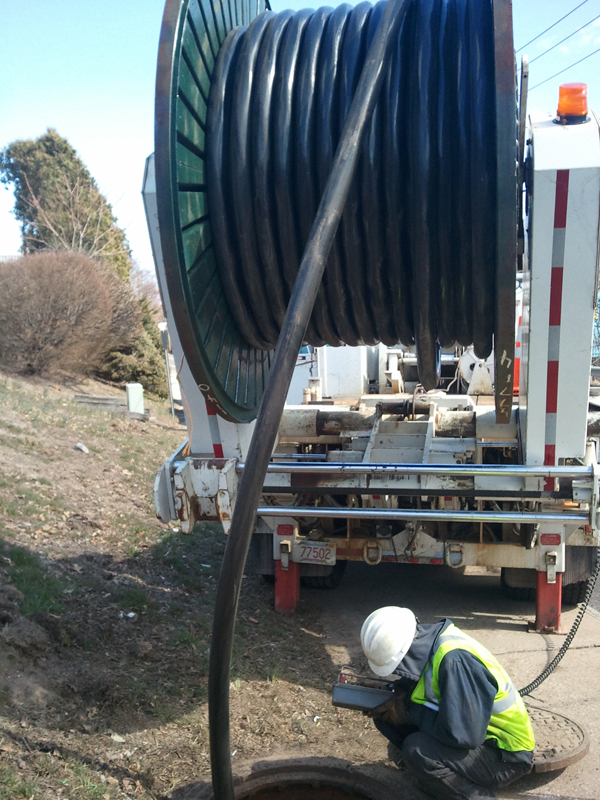

Just to advise, we do so much more than high-voltage line installation and maintenance. We support the operations and maintenance within any building’s electric system to locate, service, and or replace loose and corroded wires or connections that bring down electrical services. We identify problems with ground, circuit breakers, and miscellaneous line faults that pose risk to both person and sensitive equipment.

We’re here to help Boston business, large and small, solve and/or expand their electrical system’s capability. For more information about getting started with underground/overhead high voltage cable maintenance and repairs, or internal building electrical services, contact ElecComm.

Joseph Coupal - Thursday, July 30, 2020

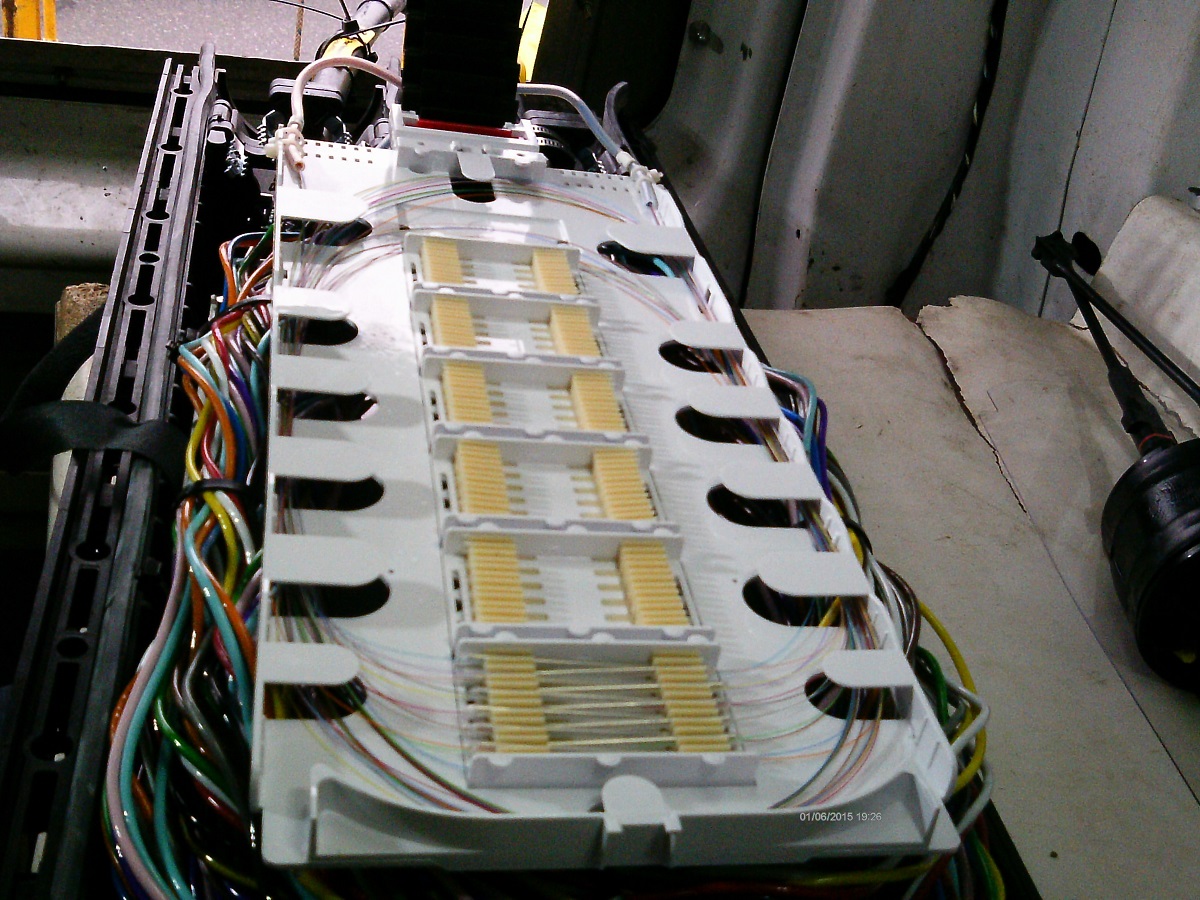

Fiber optic cable splicing is an core competency of ElecComm’s telecommunication network service offerings here in Boston. There are two types of fiber splicing services that we’ve delivered across Boston for years now: mechanical and fusion splicing.

In Mechanical Splicing, two fibers are held at both end points within a sleeve using a mechanical mechanism. Mechanical splicing is usually applied during emergency repairs and fiber testing. On the other hand, in Fusion Splicing, two fibers are welded together by an electric arc. It is the most commonly used method of splicing as it delivers minimal insertion loss and virtually no back reflection. It is the most reliable splicing method.

Fiber splicing is widely used in telecommunications and other networking projects. Both techniques are applied when repairing broken or extending functional telecommunication networks. ElecComm technicians are trained to perform both approaches. Our telecommunication services include construction, splicing, testing maintenance and restoration of fiber, copper, and hybrid fiber-coax telecommunications networks.

Should your telecommunications support need require splicing, testing, maintenance, or general repair of your telecommunications networks, contact ElecComm. It’s what we do for Boston business owners of all types.

Joseph Coupal - Thursday, July 23, 2020

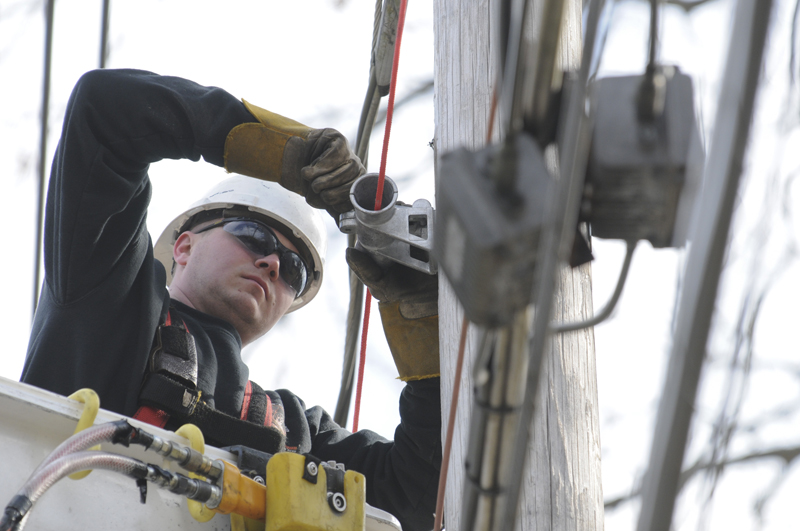

As essential construction projects gradually restart across the Northeast, demand for high voltage electric lines and telecommunication network services is ramping up strongly. ElecComm’s engineers and electricians have a proven track record for installing and maintaining thousands of miles of transmission lines throughout New England. We specialize in constructing, refurbishing, and maintaining power utility overhead lines in environments of any kind, for all types of commercial clients and industries. Our electric line construction techniques and line maintenance have kept vital electric power flowing uninterruptedly to businesses. We also provide line distribution design, voltage conversions, installation, and maintenance of primary and secondary systems.

We are proud to contribute greatly to Boston’s economic development and stand ready to assist you and your business to move forward. Worker health and safety has always been a top priority for us. We’re happy to talk anytime regarding any high voltage and or telecommunication support service that you might have. For more information on electric line construction and maintenance of power infrastructure, contact ElecComm.

Joseph Coupal - Thursday, July 16, 2020

Fiber optic networks are the backbone of modern telecommunication systems. There are times these networks require expansion, maintenance, and repair that involve segmenting existing fiber lines. Today we’re going to discuss your options for splicing your fiber optic network.

First, let’s talk about the easiest (but certainly not the preferred) mechanical splicing process. Mechanical splicing should be used for temporary fixes. The optical fibers are mechanically fixed in such a way where ends of the fibers come into contact with each other. This set-up is very prone to insertion loss and back reflection.

Fusion splicing, on the other hand, is the more reliable solution as it significantly improves signal loss and reflectance. Fusion splicing is accomplished via a specialized tool where the fiber ends are heated with electrodes, married, and fused. This method involves stripping, cleaving, alignment, and heat shrink protection of joined fibers. Fusion splicing requires sophisticated skills that only highly-trained technicians can perform. It is significantly more involved than mechanical splicing, but it offers a huge difference in network continuity and communication reliability.

Our engineers and technicians are ready to assist in any and all of your network installation and maintenance needs. For more information about our full line of information network services, contact ElecComm.

Joseph Coupal - Thursday, July 09, 2020

The golf netting system is an essential component of a sporting field. It ensures golf balls stay within the course. More importantly, they ensure the safety of spectators from injury and properties from damages over a stray golf ball. It is considered negligence to the part of the fairway owner in case an accident associated with an errant ball takes place. For all course operators, it is a primary liability concern.

Fortifying your existing golf netting system is a perfect way to safeguard the people inside the facility and properties adjacent to your golf range. Golf nets must be installed and properly maintained to properly function. We offer the highest quality golf barrier netting on the market which in turn will protect your golfers, staff, and yourself from liability.

When you need to install new or improve your existing golf netting on any Boston-area golf course, ElecComm is your trusted partner. We install poles, netting, and provide repair serves for both as well. Contact ElecComm anytime.

Joseph Coupal - Tuesday, June 30, 2020

Lush foliage covers much of the Northeast. But as the hurricane season begins, these beautiful trees can hamper the distribution of electrical power that is vital to us all. Heavy rains and strong winds coming from the Atlantic take down trees without warning. Some of these trees and branches crush overhead power lines causing electrical faults and power outages. These disruptive power outages demand prompt and professional response to limit the impact on Boston-are commerce, residential living, and yes, the environment.

The ElecComm team of engineers and technicians are highly trained, experienced, and ready to respond to these situations. Our storm response teams are trusted partners of major power utility companies and commercial industries in the New England region. Furthermore, our services have expanded to include daily and preventive maintenance of electrical poles and lines. These tasks are essential in disaster preparedness of the community.

All these services are delivered with maximum protection and awareness to our environment.

For more about our very flexible overhead lines storm response team, contact Eleccomm. We are ready and able to immediately respond to any emergency power restoration, electrical system installation, or electrical infrastructure maintenance need.

Joseph Coupal - Friday, June 26, 2020

The brutal Boston server weather has taken its toll on the area’s electrical power infrastructure. Sadly, some electric utility companies infrastructure has suffered severely and are in desperate need for upgrade and repair. We have ramped up our ability to help you do this.

ElecComm has doubled our efforts to deliver new electrical system installation, preventative maintenance services, and of course our celebrated emergency response services. We have expanded our support vehicle fleet and staff so we are more prepared than ever to respond to any and all electrical utility support need.

We provide electrical system hardening services to improve your infrastructure’s resiliency to damaging thunderstorms, nor eastern storms, and hurricanes. Structural hardening of the distribution system includes strengthening substations, and feeder circuits. Our infrastructure upgrade services includes converting wooden poles to steel, concrete or composite materials. Transmission towers can be upgraded to galvanized-steel lattice or concrete.

We can’t cover it all here in our blog. To learn more about the various electrical installation, repair, or upgrade services we’ve provided across the greater Boston area for years now, contact ElecComm.

Joseph Coupal - Thursday, June 18, 2020

Golf netting systems function as a protection to keep golf balls inside the field and prevent accidents and damage to neighboring properties. ElecComm is a dynamic company that leverages our skill sets and equipment fleet to expand beyond our electrical service specialty. In fact, we offer the highest quality golf netting solutions in and around the greater Boston area.

Benefits of Having a Durable Gold Netting System

- Legal Obligation. As a golf course operator, you are obliged to set-up a sturdy and stable golf range netting to ensure the safety of the spectators as well the properties adjacent to the golf field. When legal safety standards have been breached due to errant balls, the operators are liable and can be charged with legal penalties.

- Safety. Golf nets protect players and spectators from injury related to stray balls. As well, people passing by near your golf course.

- Protection of Property. Whether your building or your neighbor's, the golf barrier netting makes sure that golf balls won't hit and damage properties by keeping them within the driving range.

- Separates The Perimeter. Golf netting system acts as a divider that separates the golf play area from other fields or courts intended for other sports.

Since each golf course is unique, each demands a tailored golf netting system plan. Thus, it is smart to contact ElecComm to help you figure out the perfect design according to your location and natural elements that can affect the installation of your golf netting system.

Joseph Coupal - Friday, June 12, 2020

During excavation it is of utmost importance to take all the preventative actions before commencing work as outlined in the Code of Practice. One of the main dangers when digging without prior preparation is the possibility of injury from underground power cables. During digging anything in contact with live electricity cables can lead to injuries that can be fatal.

The risk of the explosive effect of arcing current and subsequent fire simply must be professionally addressed. With a slight point of a tool or when the cable is crushed severely enough to cause contact between the sheathing and one or more conductors will trigger fires or explosions.

When installing and/or maintaining any underground electrical system, it is of paramount importance to be equipped with the correct cabling map in order to know the location of power cables. We are subject matter experts in cable mapping. If the cable system is not mapped and documented at the start of our support project, it will be by project’s end. It is vital to maintain cable records and have them stored in a visible area inside your office for emergency purposes. These records provide instant definition of the essential cable voltages and the knowledgeable person on site who knows how to interpret the plans. This documentation will assist future operations and maintenance process that involve underground cable survey analysis services.

Realize that in many cases, high voltage powers cables are oil filled. When accidentally violated they are subject to flash ignition. The resulting flash electrical fire can spread to other nearby services such as gas pipes etc. Such accidents are caused by failure to take all relatively safety precautions to prevent accidental contact with underground services.

We exist to help you to install, manage, maintain, and monitor high voltage underground cabling systems affordably and effectively. For information on how to get started, contact us.

Joseph Coupal - Sunday, May 31, 2020

When June arrives, so does severe thunderstorm and hurricane season. While summer weather is bright and warm, it can turn nasty and without warning. Severe storms and hurricanes can form anytime within June to November. This always pose a threat to overhead power lines as storms bring forth heavy rain and strong winds that can uproot and knock down trees. Falling trees can be caught in pole lines eventually causing cables to snap resulting to widespread power failure.

In worst case scenarios, know that Eleccomm's emergency storm response is dedicated to assist major public utilities throughout the Northeast restoring power during major power outages resulting from storms. In addition, ElecComm (ECC) has expanded the overhead segment of its business to include, the everyday, installation, removal and maintenance of overhead lines. Moreover, we recommend upgrade of obsolete electrical infrastructures ahead of any predicted tropical cyclones for a sturdier electrical system framework. This will ensure continuous stream of electricity in your business facility amidst weather disturbances.

Know that our team is fully crossed trained and is ready for dispatch in preparation for any planned or unplanned event. Contact ElecComm for emergency power restoration, installation and maintenance of new infrastructures.

Joseph Coupal - Thursday, May 28, 2020

We’re proud of the fact that across the greater Boston area and beyond, we’re replacing old, unsightly, and increasingly vulnerable above ground high voltage cabling systems with state of the art Underground cables. The exquisite beauty of Boston really shines through in the areas that we’ve improved with this service.

Underground cabling empower municipalities and developmental communities to highlight their unique beauty without tangled poles and wires in the way. You’ve all seen the landscapes that are overpowered by unsightly utility wires and accessories. We’re helping Boston move on from those dated and costly technologies.

Whether you’re a municipality civil engineering planner or a commercial real estate developer, we’ve been assisting you for decades now with underground high voltage cable installation services here in Boston. Contact us here at ElecComm, the region’s most trusted underground cable installation and maintenance service provider.

Joseph Coupal - Thursday, May 14, 2020

When laying underground high voltage cable systems, one must understand the criticality of cold shrink and heat shrink tubing. These tubing are used for splicing, terminating and serves as an environmental seal on LV (Low-Voltage) and MV (Medium-Voltage) cables. These two types of tubes look similar on the outside but have different internal characteristics. They have different applications, installation techniques and physical properties.

Heat-Shrink Tubing is a pre-stretched shrinkable plastic tube that requires a heat source during installation. It contains a polyolefin material that is contracted to form an environmental seal protection to the joint or cable. It is ideal for industrial or commercial projects that require a chemical-resistant tubing and when serving low temperature environments.

Cold-Shrink Tubing is a factory-expanded rubber sleeve with an open end and assembled onto a supporting removable plastic core. Cold shrink tubing is installed by applying a gentle unwinding motion to release it from the core. It offers a quicker and safer installation process as compared to heat shrink tubing installation.

Cold shrink tubing is the preferred material for insulating wires, terminals, joints and connections in electrical work. You may also use it when repairing bundle of wires together and as a protection for small wires from minor abrasion. It requires to be stored in a controlled setting wherein temperature does not go beyond 43 degrees Celsius.

Both heat-shrink and cold-shrink splicing is an important step to protect spliced cables from environmental elements that may ingress within. It is an essential part of distribution circuits and DSS line re-conductoring for capacity works.

For more information about underground high or low voltage installation, contact ElecComm.

Joseph Coupal - Thursday, May 07, 2020

When your golf course’s nets wear out (which they will), and your poles succumb to mother nature and scream to be replaced, you need to act for the safety and professional appearance of your course. If your building a new course, the netting service and product that you choose makes a huge impact on both the appearance and longevity of your investment. For decades now, northeast golf course managers have trusted ElecComm to install new, repair, and upgrade golf netting systems.

A sturdy and effective netting system is mandatory to ensure the safety of the people and personal property that exist and operate near your course’s protected boundaries. Worn systems can and will result in damaged property, injury, insurance claims, and increased insurance cost as a result. Don’t let that happen to you. Our full-service delivery includes ball trajectory studies, custom netting designs, and installation options customized to your budget and operational need.

Contact ElecComm for any and all golf course safety system questions and service requirements.

Joseph Coupal - Thursday, April 30, 2020

Boston (and surrounding municipalities) are expanding and upgrading their high voltage underground cabling system at a record pace and we are proud to be part of that effort. In fact, we’ve been providing underground high voltage cable installation and maintenance across the northeast for decades now. When it comes time to laydown new or maintain/upgrade existing cable in your area, only trust the proven professionals like us here at ElecComm.

We deliver the latest in underground high voltage cable technology to include real-time monitoring capability along with strategies for simplifying the operations and maintenance aspect of your cabling system. We utilize the latest burial and jointing techniques that ensure your underground cable projects are completed on time, every time, and on budget. We employ trenchless burial techniques and directional drilling that limit adjacent property disruption to the maximum extent physically possible.

We’ll beautify your city, county, town, or developmental projects with the most low-profile power distribution systems available on the market today. For more tips on underground cables, contact ElecComm.

Joseph Coupal - Sunday, April 26, 2020

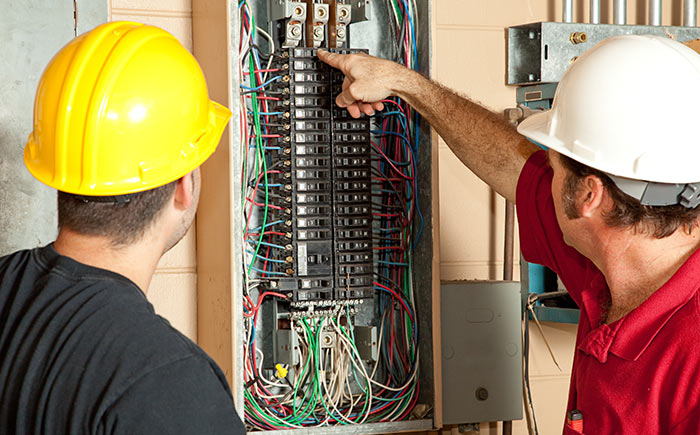

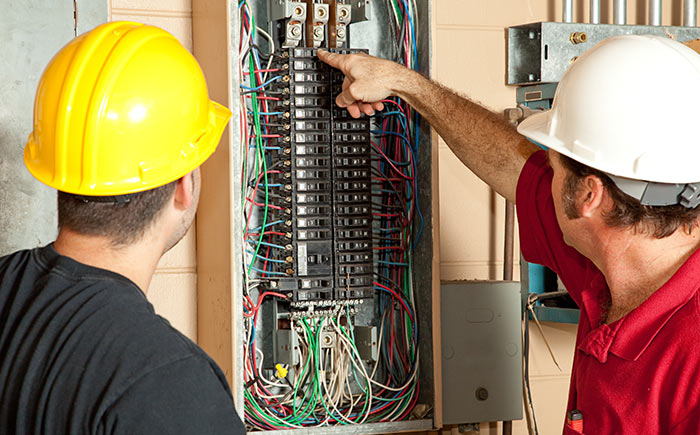

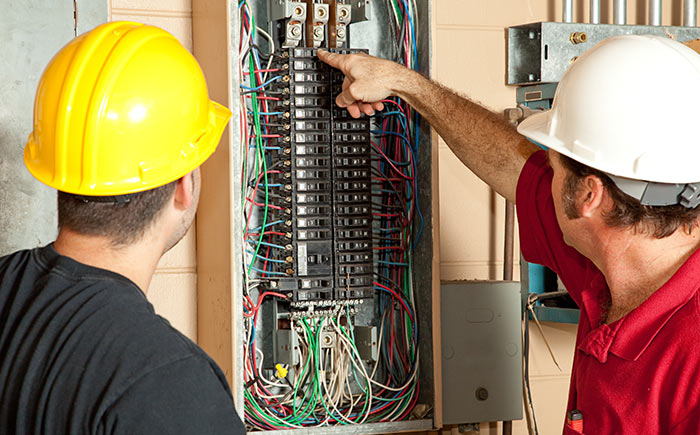

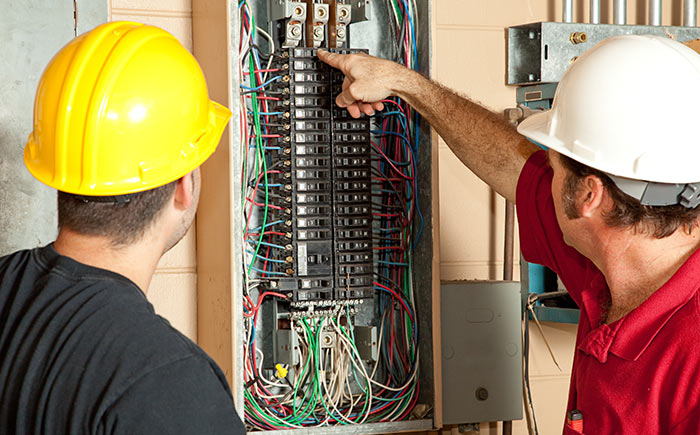

Commercial establishments require specialized electrical mechanism to prevent fires, system malfunctions, risking lives and properties. Everyone is exposed to electrical hazards, but shocks and burns from faulty wiring at any business establishments can result in horrific consequence. Circuit breaker protection plays a major role as it is used with grounding for the protection of electronic overloading and heat build-up. It is absolutely essential nowadays because the safety mechanism of this equipment fully guards a structure and its occupants against the electrical hazards like faulty wiring, improper grounding, short-circuit, voltage fluctuations, etc.

Circuit breakers require more maintenance to ensure that they are fitted with genuine parts. It is common that the function of circuit breakers is negatively affected when genuine replacement parts are not available that will result in frequent repairs, stoppage time and power failures. Likewise, the durability and longevity of a circuit breaker also depends on the magnitude of the breaking current. Likewise the ideal function of circuit breaker protection is it easily detects a fault condition and by interrupting the continuity it immediately discontinue the electrical flow. A circuit breaker will be reset either manually or automatically to resume normal operation.

Electrical system maintenance and repairs are very important though main considerations are services cost and the availability of genuine replacement parts for corrective maintenance. It gives a direct impact in the life of circuit breakers if replacement parts are available because the outage time will be significantly reduced. There are several safe and effective methods to extend the service life, durability and dependability of circuit breakers using replacements and reconditioning. Adding more some incorporating advanced technology will improve the life expectancy of the circuit breaker and keep it in good shape even beyond its service life.

For more tips on circuit breakers maintenance and repairs, contact ElecComm.

Joseph Coupal - Sunday, April 19, 2020

It is essential that every distribution circuit within a wiring system is protected against overload. A circuit overload occurs when the amount of current flowing through the circuit exceeded the rating of the protective devices. The reason is that all electrical circuits are designed to handle a limited amount of electricity. There is overload when you draw more electricity than a circuit will safely handle. Circuits are made up of a breaker, fuse for old wiring systems, and devices like light fixtures, appliances etc. The electricity usage of each device when running will add up to the total load on the circuit. In case there is no breaker in the circuit, the circuit wiring will overheat which will melt the wire insulation leading to a fire.

First and foremost in preventing electrical circuit overload is to learn the maximum amperage that will be demanded from the circuit. Once you have mapped the basic circuit layout, calculate the safe load rating of each circuit to get the exact value of how many things you will operate on that circuit. Mapping the circuits also will tell if there is a need for new circuits to meet the normal needs. Another protection for electrical units is protecting the actual electrical wires supplying the circuits against an overload that will exceed their carrying capacity. Furthermore, protecting from an overload the individual appliances and electrical equipment connected to a supply circuit. Remember that different circuits have different load ratings such that some circuits will provide more electricity than others.

In order to prevent electrical overloads, circuit breakers and fuses are designed to trip or blow, stopping the flow of current to the overloaded cable. Likewise, overload protection is protection against overheating. It operates at a slow pace. A thermal-magnetic circuit breaker is an example of protection in one device. And while circuit breakers are reliable and doing an excellent job preventing open fire due to overloads, the safest strategy is to manage your electricity consumption to prevent overloads in the first place.

For more electrical safety tips, contact ElecComm.

Joseph Coupal - Sunday, April 12, 2020

Upgrading obsolete communication networks to fiber optic cables offers a host of advantage. Fiber optic cables have a much greater bandwidth than traditional copper cables therefore they transmit significantly higher data as compared to other transmission means. Here are other reasons to consider a fiber upgrade to your data system:

Minimal Power Loss

Since optical fiber present minimal power loss, data transfer can reach longer distances. In contrast with copper, the only recommended copper distance in a network is 100m whereas optical fiber can go up to 2 km.

Unaffected To Electromagnetic Interference

Optical fiber cables are unaffected to electromagnetic interference. Moreover, it can work in electrically loud settings without issues because electrical noise doesn't seem to influence the fiber.

Greater Capacity

Fiber optic cable has approximately 4.5 times much capacity than copper because wire cables has cross sections that is 30 times short.

In comparison to copper, a fiber optic cable has nearly 4.5 times as much capacity as the wire cable has and a cross sectional area that is 30 times less.

Thinner and Lighter Weight

In terms of weight, optical fibers are thinner and lighter when compared to metal wires. It also take up minimal space with cables of the same data capacity. And Since they are lightweight, fiber optic cables are easier to set-up.

More Secure Data Transmission

Since fiber optics do not radiate electromagnetic energy, the emissions are not intercepted. This makes fiber the most secured means there is for transmitting confidential information as manually tapping it requires lot of skills to perform it undetected.

Flexible

Optical fiber are incredibly flexible with excellent tensile strength. It is also resistant to corrosive factors that easily affect metal wires.

Minimal Cost

Simply, the raw materials for fiber optics are glass which a lot more cheaper than copper.

For more information about fiber optics, call Eleccomm.

Joseph Coupal - Tuesday, March 31, 2020

With the rising number of residential and commercial properties, the growing number of private and municipal golf courses, the demand for golf-related safety systems such as quality golf course poles and netting solutions are naturally on the rise as well.

Allow us to introduce you to another field of excellence that your trusted partners here at ElecComm provides to the greater Boston area and beyond. Our steel pole and netting systems for driving ranges, golf clubs and fairways across New England are protecting golfers and course owners alike and have been for decades now. Our services include pole & netting design and installation, replacement and protection netting. We customize netting systems according to the location and weather conditions. Contact us for a golf course safety consultation. We’ll gladly discuss with you ball trajectory studies, custom netting designs, installation options, and much more.

For information regarding golf netting installation and maintenance services, contact ElecComm.

Joseph Coupal - Thursday, March 26, 2020

If you are looking for certified professional engineers in Boston to deliver commercial electrical project management, design, and installation of underground high voltage cabling systems, ElecComm is the company Boston has trusted for decades.

Our team of certified engineers can perform and manage construction, splicing, testing, maintenance and restoration of fiber, copper, and hybrid fiber-coax Telco networks across New England. We have laid and spliced thousands of miles of cable up to 35,000 volts. We are one of the largest electrical and communications line construction companies in New England. We deliver immediate 24/7 emergency and routine service response.

ElecComm's core business focus is on the installation, removal, and maintenance of overhead and underground electric/communications distribution systems. Contact ElecComm for any overhead and underground cabling system concerns or to learn more about our other services.