Joseph Coupal - Thursday, October 10, 2019

High quality netting systems are a great investment for your golf course or range. Golf barrier netting is an essential piece of athletic equipment to ensure that golf balls stay where they belong; within the range or course. In addition to this, Golf Netting Systems keep both spectators and property safe from the damages associated with errant golf balls.

If you are the owner of a fairway or driving range, you are under a lawful commitment to safeguarding the viewers and homes surrounding the fairway or driving range. There are many brands of Golf Netting Systems, but not all are created equal.

This is why extreme caution must be taken when selecting the best Golf Barrier Netting System so that you get the best return on your investment. There is a need to upgrade the high-quality Golf Ball Barrier Netting System.

Below you will find the best additional benefits of having an efficient Golf Netting System at your course or range.

- There are many legal reasons for installing a Golf Netting System at your range or course. Protecting golfers, their belongings, the vehicles nearby, and the spectators are the duty of the owner. Golf Nets can be installed in areas where an errant golf ball can create a potentially dangerous situation. It is imperative that said a system is properly installed to comply with all applicable laws and in order to prevent lawsuits.

- Golf Netting is imperative to ensure spectator and player safety throughout the duration of a competition. With the addition of a Golf Netting system, you will be able to protect both players and spectators from being injured.

- Golf Netting is the ideal solution to protect course or range property as well as a golfer and spectator property (for example cars in the parking lot). In addition to this, Golf Nets are an ideal solution for situations when a passer-by could become a target of a poorly hit ball.

- Golf Nets also give you the ability to separate areas of the course from others. To put this into perspective, if a busy golf course also supports a driving range, a Golf Netting system is fundamental in establishing a barrier between the two.

Factors such as the safety needs of the area, surrounding properties, common weather conditions, efficiency, productivity, visual comfort and UV protection should all be taken into consideration. It is clear that the importance of Golf Netting Systems cannot be denied but not all nets are made equal making it necessary that you conduct research to determine the best netting system for your specific application.

For more tips on golf netting solution, contact ElecComm.

Joseph Coupal - Tuesday, October 08, 2019

Measuring dielectric properties is an important aspect of improving the design of electrical equipment. Dielectric testing validates the quality of insulating conductors and other electronic components. The importance of testing electricity within materials is undeniable, but having the right tools and expertise is the only way to get meaningful results.

To get a better understanding of dielectric measurement techniques, we've detailed six methods that are commonly used:

Coaxial Probe – This serves as the most commonly used method for measuring permittivity in materials. A metallic probe is pressed against the material or immersed in a liquid to measure reflection coefficient, which determines the permittivity. It is a simple method that enables the user to collect measurements over a wide range of frequencies.

Transmission Line – Another method commonly used in dielectric measurement involves placing a sample on a coaxial line, or waveguide, and then measuring complex scattering parameters with a VNA analyzer. The transmission line method uses both reflection and transmission to gather measurements with higher sensitivity than the coaxial method.

Free Space – Free space is a method of testing electricity across a wide band of frequencies. Large, flat samples of materials are placed under extreme heat and in hostile environments for a dielectric measurement. The advantage of this testing method is having the ability to grab reflection and transmission coefficients without any contact. Additionally, both electrical and magnetic properties of the material can be evaluated.

Resonant Cavity – This method collects measurements with high accuracy and high-temperature support. You can also get accurate results with dielectric loss materials. This method is based on the shift in resonant frequency of a tuned cavity when a loss material serves as a resonator.

Parallel Plate - To run this test, the tester must sandwich the dielectric material between two electrodes to form a capacitor. Then, measurements are taken from an LCR meter or impedance analyzer with a dielectric test fixture. This method is typically used to measure low frequency materials.

Planar Transmission Line – This method of testing material in RF and microwave components utilizes a microstrip line. Fabrication is simple and its compact nature makes it suitable for most industrial applications. With this form of testing, dielectric measurements are deduced from a change in permittivity utilizing suitable expressions.

As with any type of testing or measurement, it’s always important to address variables such as frequency, accuracy, temperature, material or anything that’s important to your application. To learn more about dielectric measurement and testing, contact ETS Inspection and Testing Services.

Source: https://www.matsolutions.com

Joseph Coupal - Monday, September 30, 2019

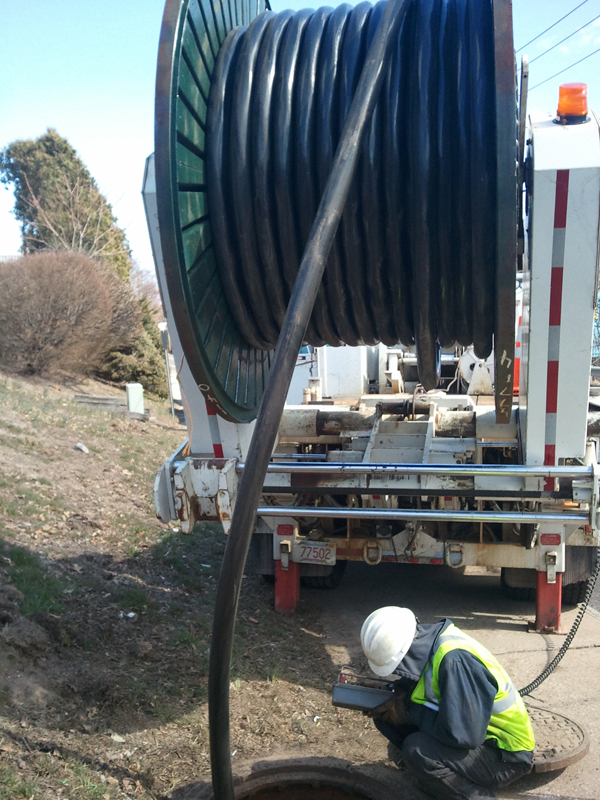

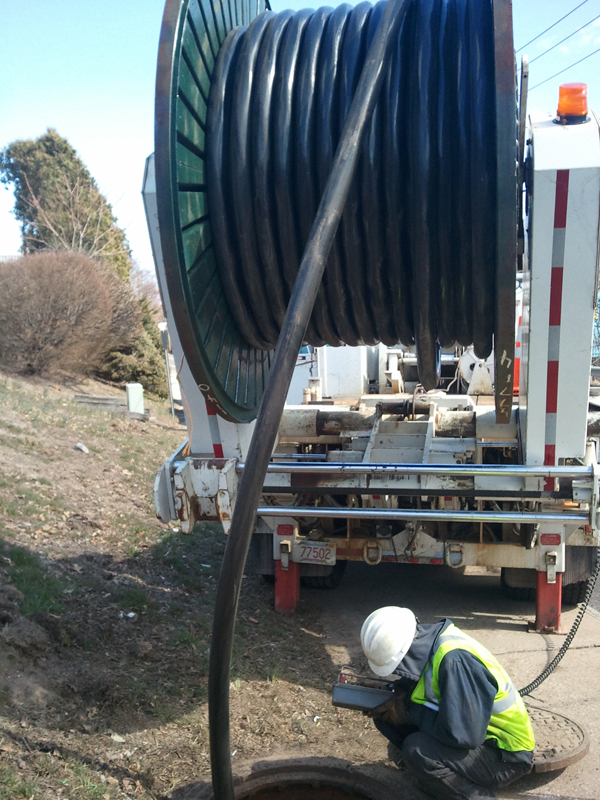

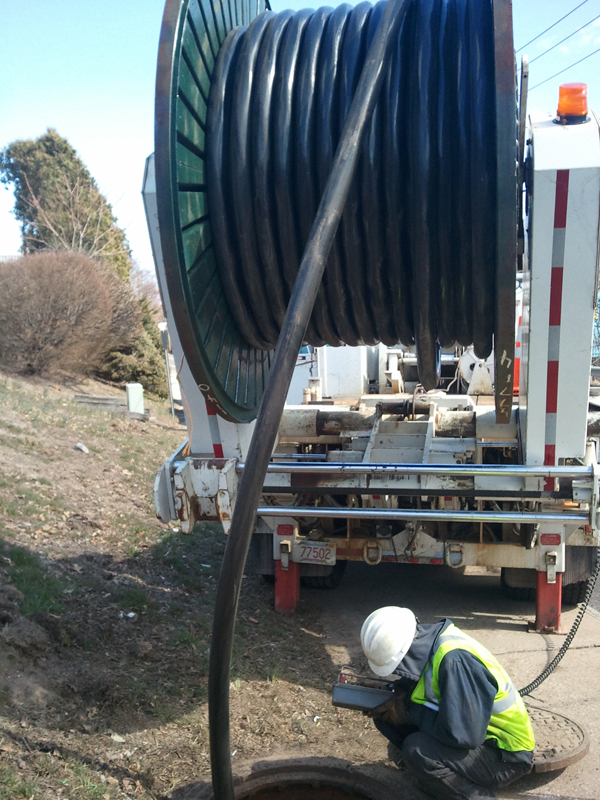

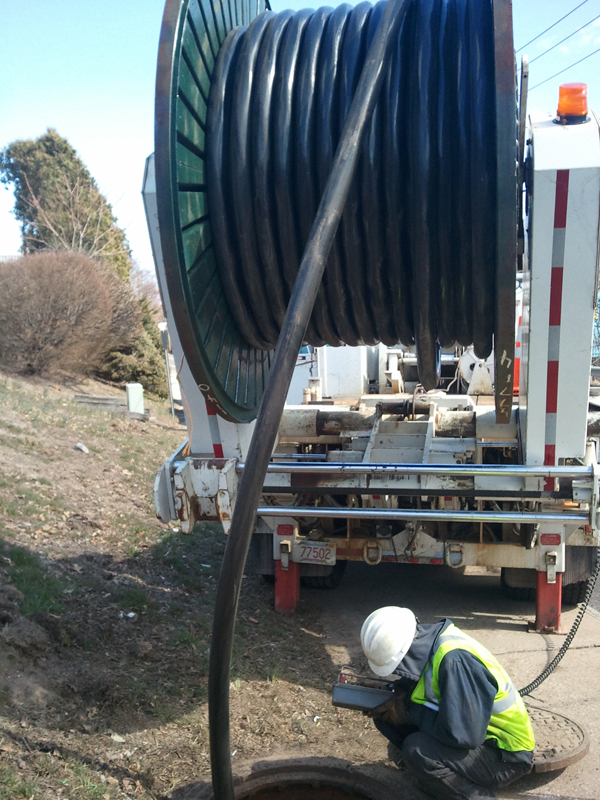

There are several advantages that are associated with the laying electric cables under the ground for transmitting electricity.

The following is a brief outline of these advantages.

Compared to overhead cables, underground cables are much safer. This is because underground electric cables are not exposed to the many dangers that ead power cables are exposed to.

It is cheaper to maintain underground cables over the course of time as compared to overhead ones. In practice, the cost of installing underground cables far exceeds what is associated with the installation of overhead ones. But once the underground cables have been installed, it is highly unlikely that will have to be repaired every now and then as it is the case with overhead electrical cable types.

Underground transmission of electricity is associated with reliability. This is because instances of constant disruption in the supply of power as a result of storms or faults that are associated with overhead transmission lines are not common when power transmission lines are laid underground.

For more information contact me ElecComm.

Joseph Coupal - Thursday, September 26, 2019

Setting up a communications platform for your business is an enormous challenge. This task must be accomplished by seasoned professionals. There are countless moving parts, numerous applications and protocols that must communicate with each other, and tremendous difficulty involved in all of the above. We handle your future problems and take the worry out of the telecom software process. Rely on our experienced programmers to stop the roadblocks before they happen and get your telecommunications up and running.

Over the years, we have been creating telecom solutions for infrastructure management and system integration, helping telecom-focused ISVs, mobile and fixed-line operators, VoIP providers, and broadcasting companies increase the number of clients and reduce network maintenance costs.

Our value added services offered brings about customized solutions to your telecommunications network services. As we adopt the latest upgrades in the technological field, we are also able to employ various methodologies to advance connectivity and communications both locally and across national boundaries from the core of your network.

We provide tailored solutions and telecommunications services to resolve your technical difficulties, leaving you free to focus on enhancing service value to your end customer and generating more revenue. Greet the lifestyle of an evolving digital communications era with state-of-the-art communications services for tech-savvy business consumers.

In today’s rapidly advancing technological age, valuable data and various networks are key features of governmental and business management. The recent rise of hacking attacks such as DDoS, Phishing, or Ransomware are creative exploits to steal proprietary information and a disruption of critical services.

With our solutions, layers of defense are strategically positioned at the edge and within the network to prevent unauthorized access. We ensure a prominent level of quality service and maintain cyber security for our clients so that network information is fully hack-proof. Our telecommunications services also include perimeter defense.

If you have inquiries about telecommunications network solutions, contact ElecComm.

Joseph Coupal - Thursday, September 26, 2019

Telecommunications and network security is incorporated within transmission methods, transport methods, transport formats, and software. The collective security strategy ensures confidentiality, integrity, and availability:

- Confidentiality is making sure that only those who are supposed to access the data can access it. Confidentiality is the opposite of disclosure.

- Integrity is making sure that the data has not been changed by accident or malice. Integrity is the opposite of alteration.

- Availability is making sure that the data is accessible when and where it is needed. Availability is the opposite of destruction.

The Telecommunications security domain of information security is also concerned with the prevention and detection of the misuse or abuse of systems, which poses a threat to the tenets of Confidentiality, Integrity, and Availability (C.I.A.).

We need to predict, prevent and protect against risk with cyber security. Cyber threats remain one of the top risks the world faces in today’s hybrid IT telecommunications environment – and they are constantly evolving. As a result, cyber security is critical to any digital business. Our cyber security solutions enable your organization to be secure-by-design, minimizing cyber-risk throughout your workplace. We will clarify your data protection experience, helping you innovate and digitally transform, at your own pace.

Regardless of your good intentions, if you are not making a next-generation firewall part of your plan, your data center’s security posture is probably porous. It is time to strengthen your telecommunications data center security design.

If you have inquiries about security in telecommunications network, contact ElecComm.

Joseph Coupal - Wednesday, September 25, 2019

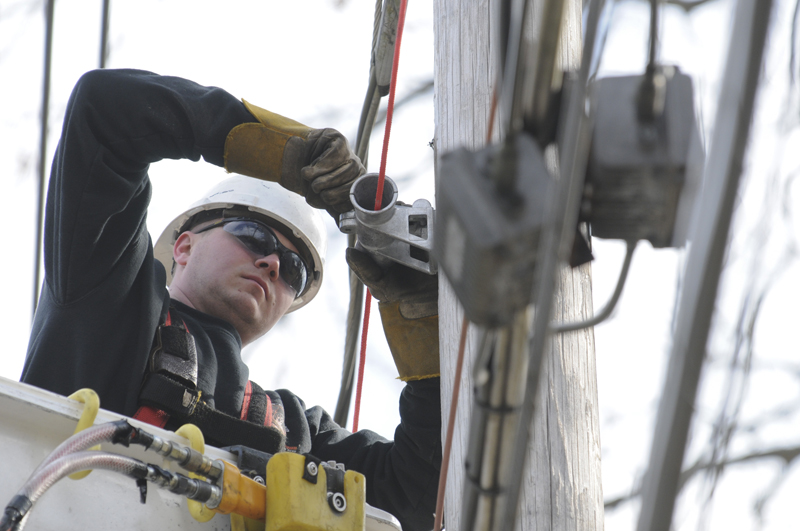

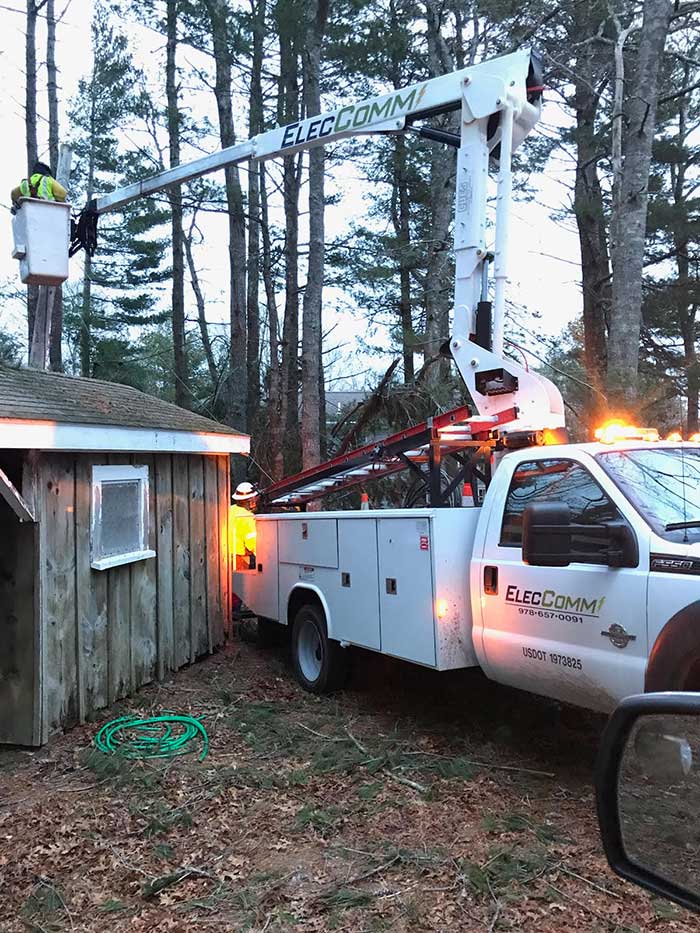

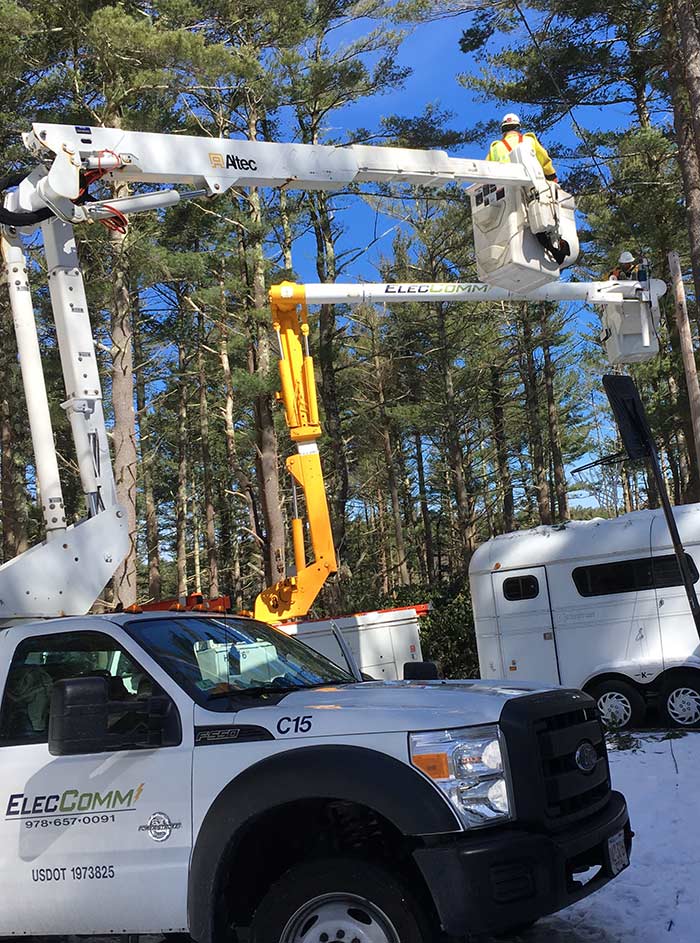

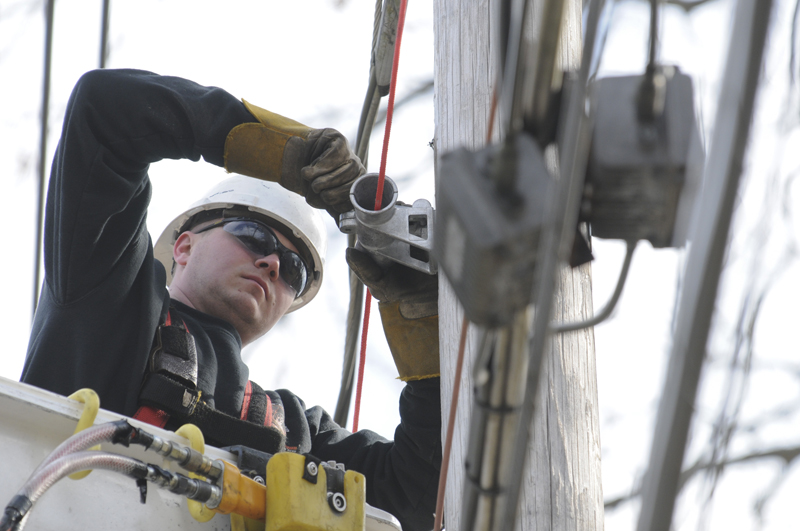

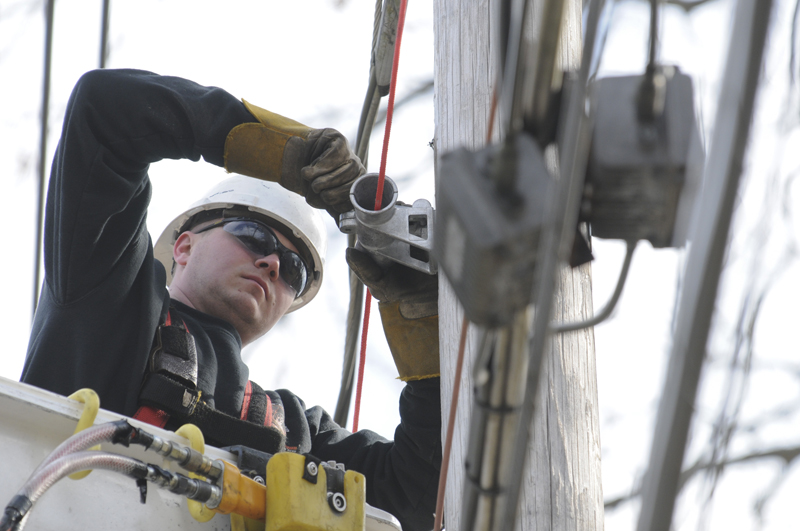

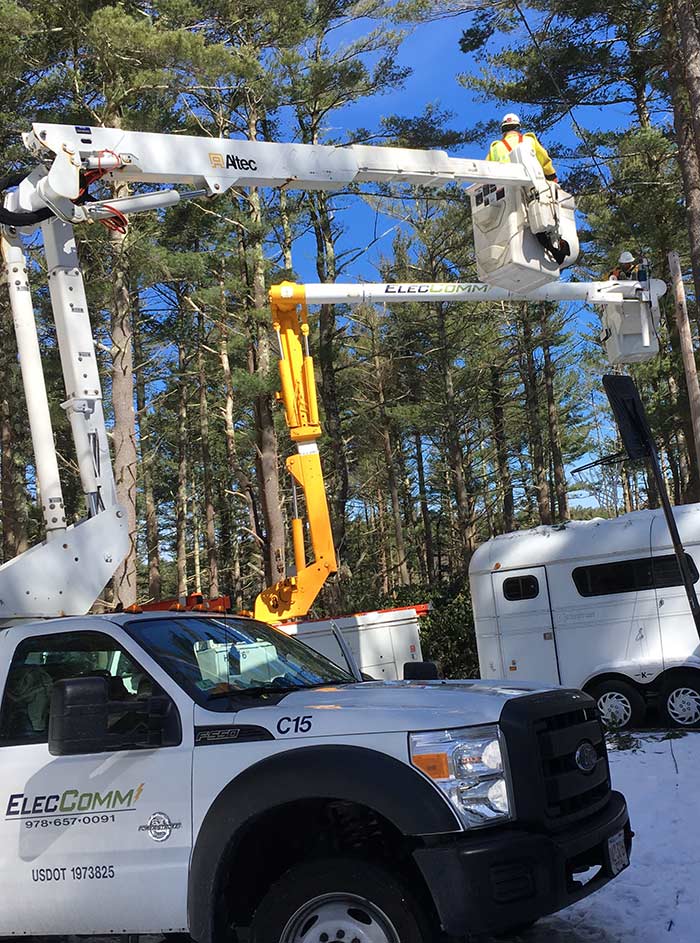

This blog post lays out a number of reasons why any business owner who employs aerial lifts to seek regular and recurring high-voltage dielectric testing. Testing is critical to guaranteeing the safety of your staff, equipment, and the systems you are employed to service. Below we offer you ten aerial lift safety tips:

Tip #1: All Aerial Lift Operators Must Be Trained

Majority of aerial lift accidents are due to human error. Proper training is the best way to prevent mishaps while operating the equipment. Operators must comply with OSHA's requirements and training.

Tip #2: Equipment Inspections Must Be Done Prior Each Shift

Pre-start inspection must be performed before operating an aerial lift. This routine checkup enables operators to detect any potential hazards or defects that may pose threat to safety. The inspection process covers both vehicle and lift components.

Tip #3: Follow Manufacturer’s Instructions When Operating The Lift

The manufacturer's instructions include particular details about the equipment. The weight and height capacities are noted, as well as the limitations that should not be exceeded to prevent untoward incidents while operating the unit.

Tip #4: Never Disregard Safety Devices

Aerial lift safety devices provide protection to operators from pressing the lift beyond its limits and results an accident such as mechanical malfunction or a tip over.

Tip #5: Never Move the Lift with the Platform in High Position

Workers are at risk of falling when they try to move the lift while staying on the platform.

Tip #6: Never Position Aerial Lift Between Overhead Objects and the Bucket

Overhead objects, signs or structures which may get in touch with workers inside the bucket can possibly crush them when the lift is situated too near the object.

Tip #7: Maintain a 10-Feet Distance Between Power Lines and Assume They are Live

Keep at least 10 feet distance between the power lines and the lift. Always assume that these power lines are live even if they are lying in the ground. Rubber gloves, hard hats, and rubber soled shoes are required to be worn within the job vicinity.

Tip #8: Protective Gear Must Be Used At All Times

Aerial lift operators working in raised platforms must wear full body harnesses connected to boom or basket straps. These protective tools prevent workers from being thrown out from the basket and hit the ground. Guardrails are not meant to be used for sitting, standing, climbing or even to support stability. Always check job site safety protocols before beginning work.

Tip #9: Place Aerial Lifts on Stable, Even Ground

Aerial lifts should be situated to stable or even grounds. When it's necessary to place it in an inclined position, make sure to set the brakes and use wedges on the wheels to prevent it from rolling. Outriggers should also be utilized when provided.

Tip #10: Do Not Exceed Aerial Lift’s Load Capacity

Although aerial lifts are extraordinarily capable equipment, they also have limitations. Always refer to manufacturer's instruction manual regarding its weight and height limitations before using it for loading. Be reminded that the weight limitations of the lift also include the tools and other accessories in the bucket besides the workers. Take time to calculate it to ensure worker's safety and prevent tip over accidents.

Lastly, make sure to submit aerial lifts for regular high-voltage dielectric testing to identify any defects and perform necessary repairs in order to prevent it from further decay and deterioration. Contact ETS Inspection and Testing Services for aerial lift testing and repairs.

Joseph Coupal - Thursday, September 12, 2019

When it comes time to net your driving range and golf course, know that quality barrier nets will save you huge sums of money over the long ter. Our golf netting is made of the finest quality materials and is professionally installed by our experienced team, so that your commercial golf net is built to last. Custom golf netting is vital as it can keep long drives on the course where they belong and away from yards, windows, cars, and neighborhood homes. Our superior quality nets will provide valuable protection for adjacent neighbors.

Our professional team are trained and experienced in commercial net installations. We have completed a wide variety of installations with projects ranging from 25 feet to 125 feet tall, and can install taller nets if needed. We handle the entire installation job from start to finish. Our process includes:

- Working with you on the design and general consulting of your custom netting project

- Running all necessary cabling, hardware and rigging

- Sewing a poly rope border into the sections of netting

- Stretching all cables and hanging netting

We know that every customer has different needs and different applications. That is why we bring all of our experience and expertise to every golf course and driving range netting installation job. The team members are your netting design and installation experts. Golf netting, driving range netting and landfill/debris netting are not sidelines for us; they are our only focus.

The growth of the game of the golf only continues to move forward. The consistent need for golf netting that covers a wide range of needs for individuals, golf courses, and even driving ranges gives us the ability to promise you that regardless of what you may need in the way of custom golf netting, we can help. When it comes to golf netting that will suit your needs, there are things to keep in mind. It is important to purchase netting that is going to meet your needs for the present and another to take a long-term view of what you are going to need from your golf netting. We can help to ensure you choose something that is going to be absolutely perfect.

Our netting products are made from the finest materials to be found anywhere. There are demands for netting that vary from one range to another, from one course to another. From fabricating steel poles for driving range netting, to taking into account the homes/businesses near-to your golf course, home, or range, there are a number of smaller considerations within any larger project. You want to make sure you are working with a company that will take each of these considerations seriously. The end result will be netting that you will be able to rely upon for years and years to come.

We are going to make sure everything is being taken care of. From the design and general consulting of the project at its beginning, to make sure all of the relevant cabling, hardware, and rigging are taken care of, we are going to be there to handle absolutely everything. This includes sewing poly rope borders into the proper sections of the netting, and making sure all of the cables have been stretched properly as we work to hang the netting.

With our company, every installation is custom fit for the job at hand. We work with you to ensure that you get the perfect custom net installation for your needs. We see every project through from start to finish. We want you, our customers, as well as your customers and neighbors, to be happy with every installation we do. That is why we work to ensure your complete satisfaction.

If you have inquiries about custom golf netting installation, contact ElecComm.

Joseph Coupal - Monday, September 09, 2019

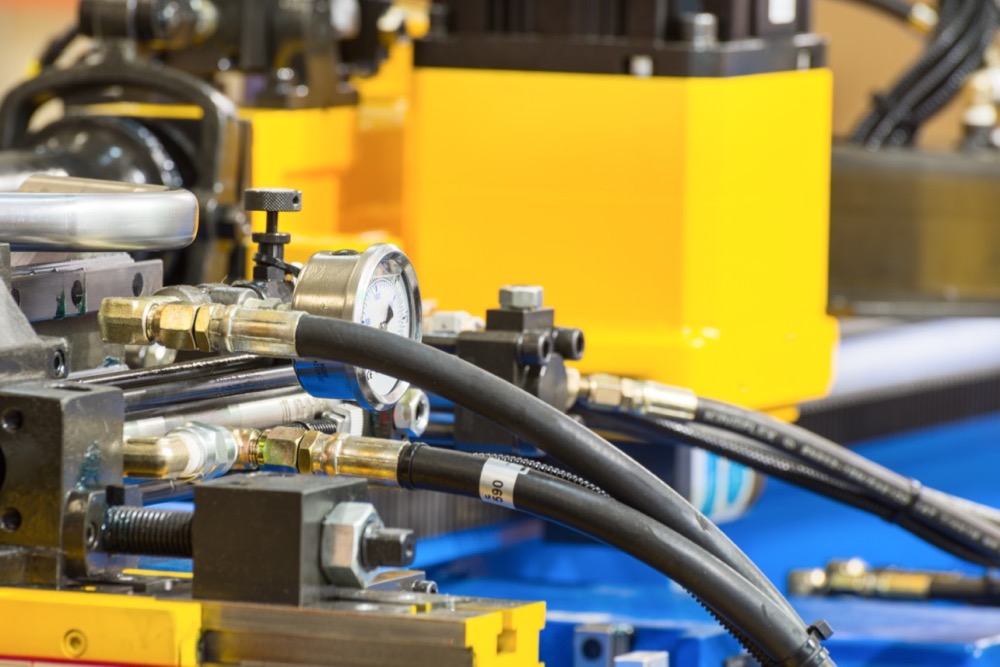

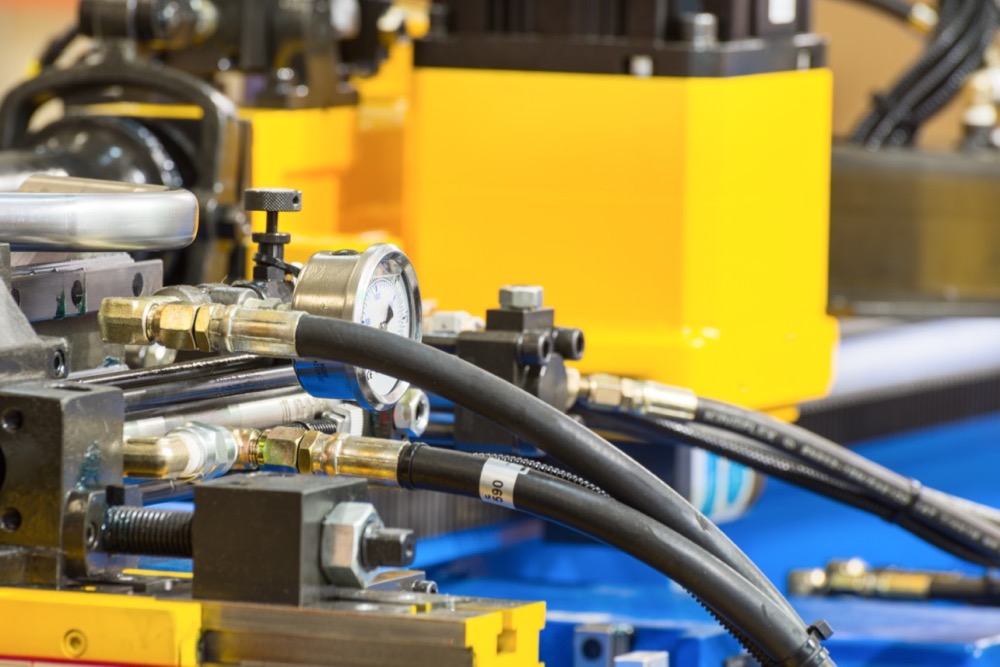

A cylinder definitely calls for professional repair when you notice any leaking or power loss. When repairing hydraulic cylinders, your servicing professionals will perform the following steps:

Step 1. Disassembly - Remove the cylinder from the equipment. Take off the cap. Loosen the input valves to reduce the pressure and pull out the piston out of the cylinder to check for any damage or defects.

Step 2. Inspection - Visually inspect the piston to determine the problem. If there's a bent in the piston shaft or a scratch in the Cylinder Bore, you need to send it to a professional hydraulic repair service to fix it. A specialized machine and skills are required to create a new shaft or honing of the cylinder bore. This must be done to eliminate the scratches and restore the seal. If the shaft and honing have no issues then it is likely a damaged seal that is causing the leak.

Step 3. Repacking The Seal - Acquire a seal kit for your specific cylinder. The seal kit has all the needed seals and O-rings required to replace the damaged ones. Carefully, remove the old seals and exactly replace it with new ones in place. Be extra careful when handling the seals. Make sure you don't damage it in anyway. Otherwise, you have to repeat the process again.

Step 4. Re-assembly - Oil the seals using an oil or a hydraulic fluid and carefully, slide the piston back inside the cylinder. If it is hard to push the cylinder back due to pressure, check the input valves and loosen it to let the air out. The piston should easily be moved back and forth. If you think it is too tight, check the seals if they are in place. When the piston is already in, put back the cap. Test the cylinder first prior to re-attaching it to the equipment. Connect the hydraulic hoses and check for leaks.

If you think the task is way out of your league, contact ETS Inspection and Testing Services. We guarantee quality repair of your hydraulic cylinder to extend its life for longer.

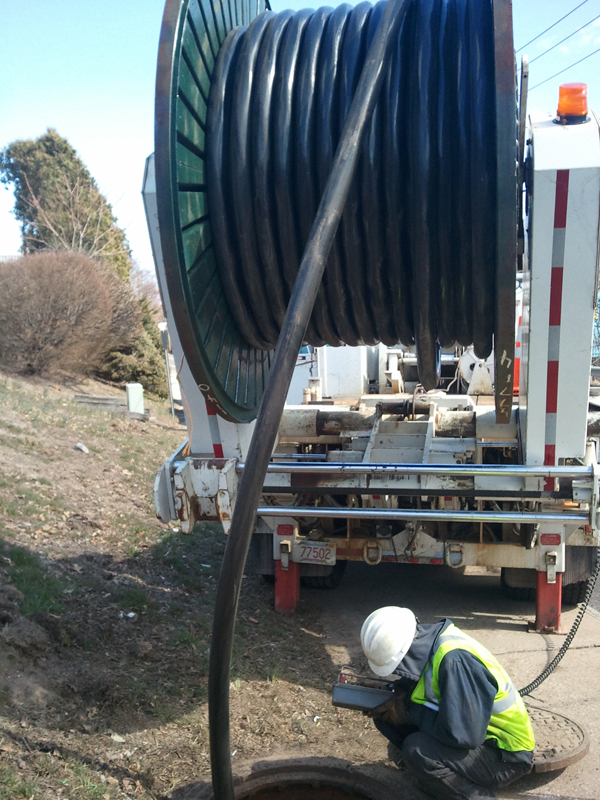

Joseph Coupal - Wednesday, August 28, 2019

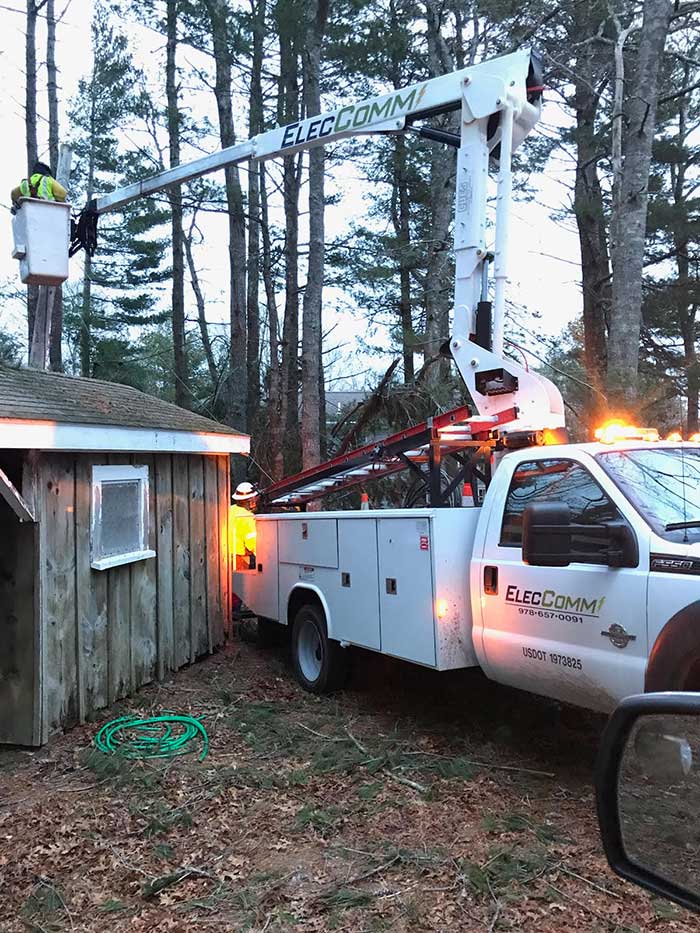

ElecComm continually looks to add new experienced or entry level talent to our expanding workforce. Our team is distributed throughout New England and we encourage applicants from surrounding states. ECC is a UWUA local 369 company.

ECC takes pride in our team and offers a well-rounded benefits package that includes comprehensive medical and dental coverage, a 401(k) plan with company match, profit sharing plan, life and disability insurance as well as paid time off.

We pride ourselves in safety, health, training and state of the art equipment for our employees and participate in the UWUA Apprenticeship Program. Our team is continually cross trained and upholds the highest safety standards in the workplace. ECC is an equal opportunity employer.

Please submit your resume to info@eleccommc.com

Employment Opportunities:

- UG Lineworker Leader

Responsible for the installing, and constructing of plant and equipment. Directs and trains employees of an equal or lower rating. Incubmbents work under general supervision. More info...

- UG Lineworker Class 1

Responsible for the installing, and constructing of plant and equipment. Directs and trains employees of an equal or lower rating. Works under general supervision. More info...

- UG Lineworker Class 2

Responsible for the installing, and constructing of plant and equipment. Directs and trains employees of an equal or lower rating. Works under general supervision. More info...

- UG Lineworker Class 3

Responsible for the installing, and constructing of plant and equipment. Works under general supervision. Works under directive supervision when installing cable or equipment.More info...

Joseph Coupal - Wednesday, August 28, 2019

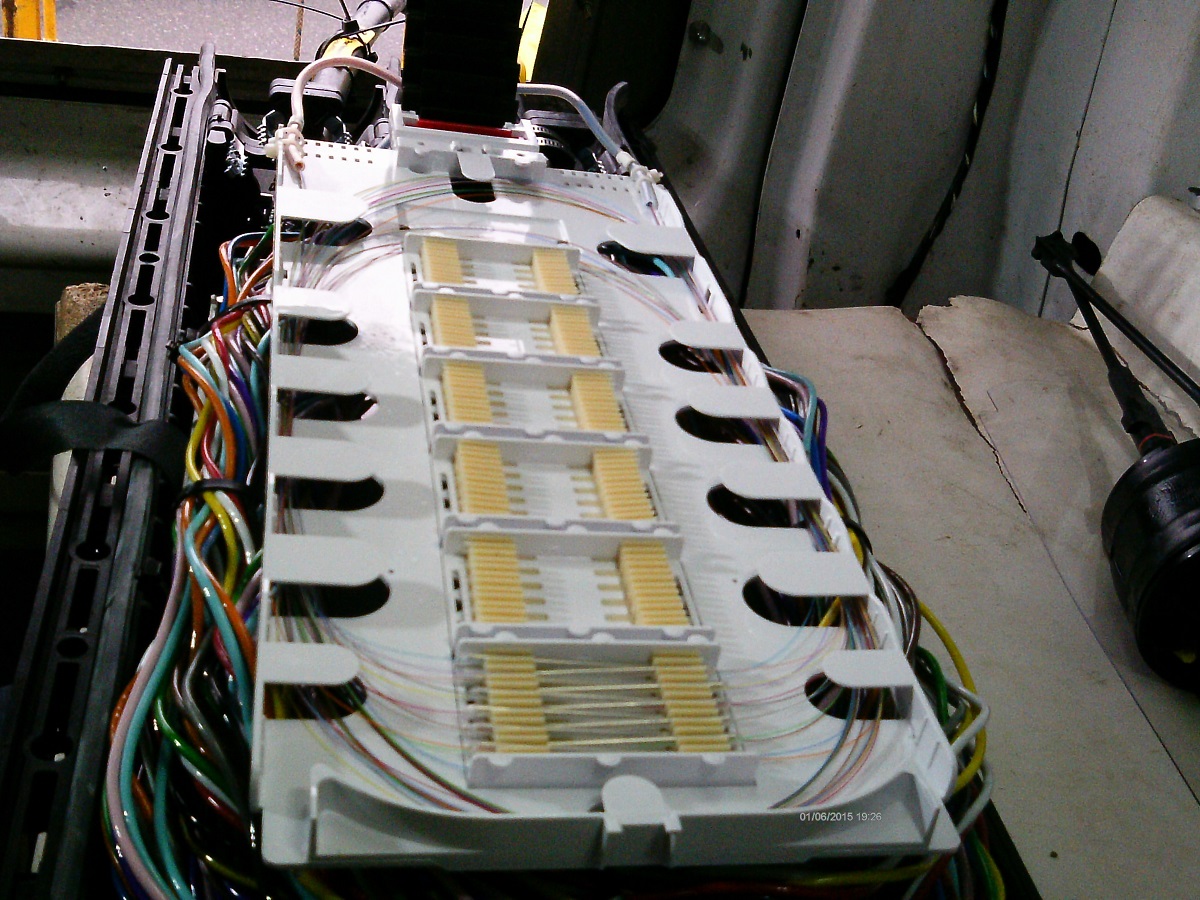

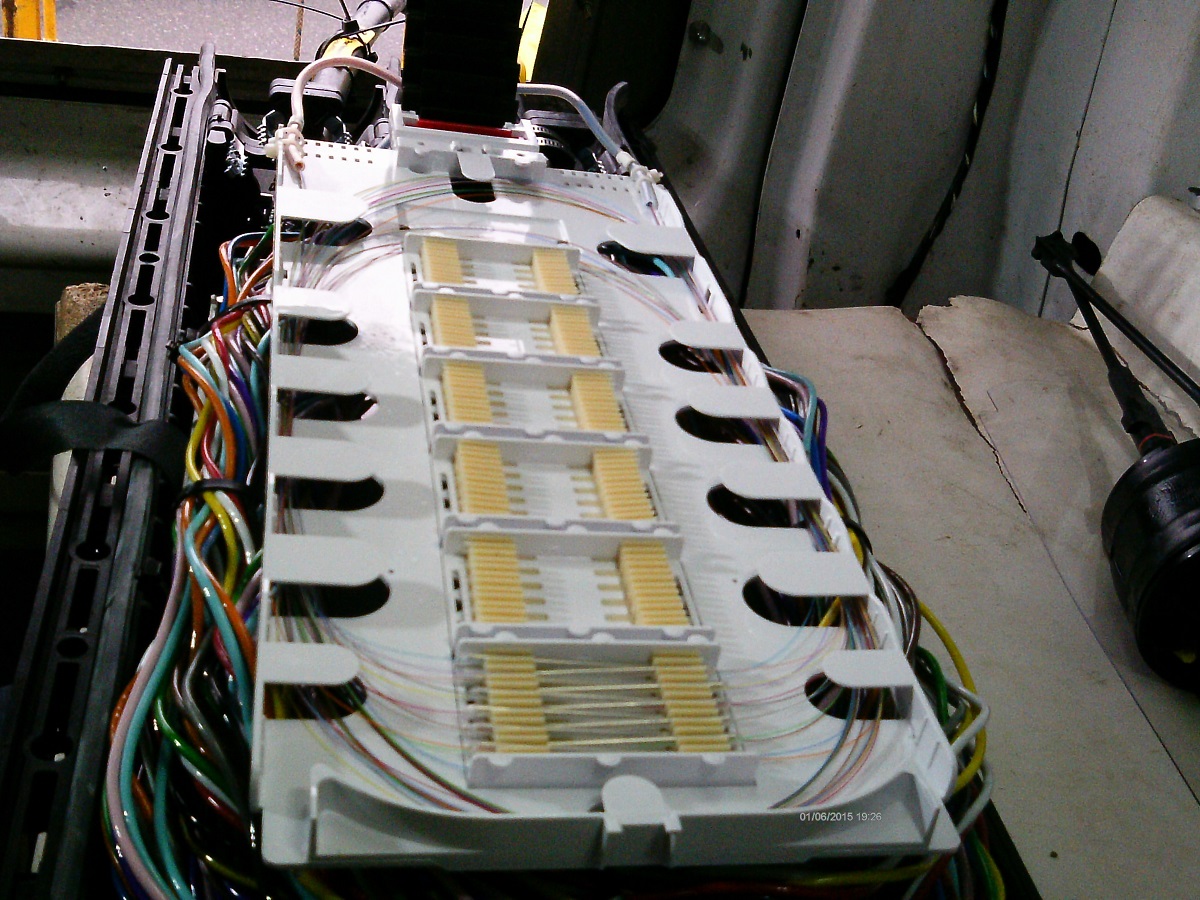

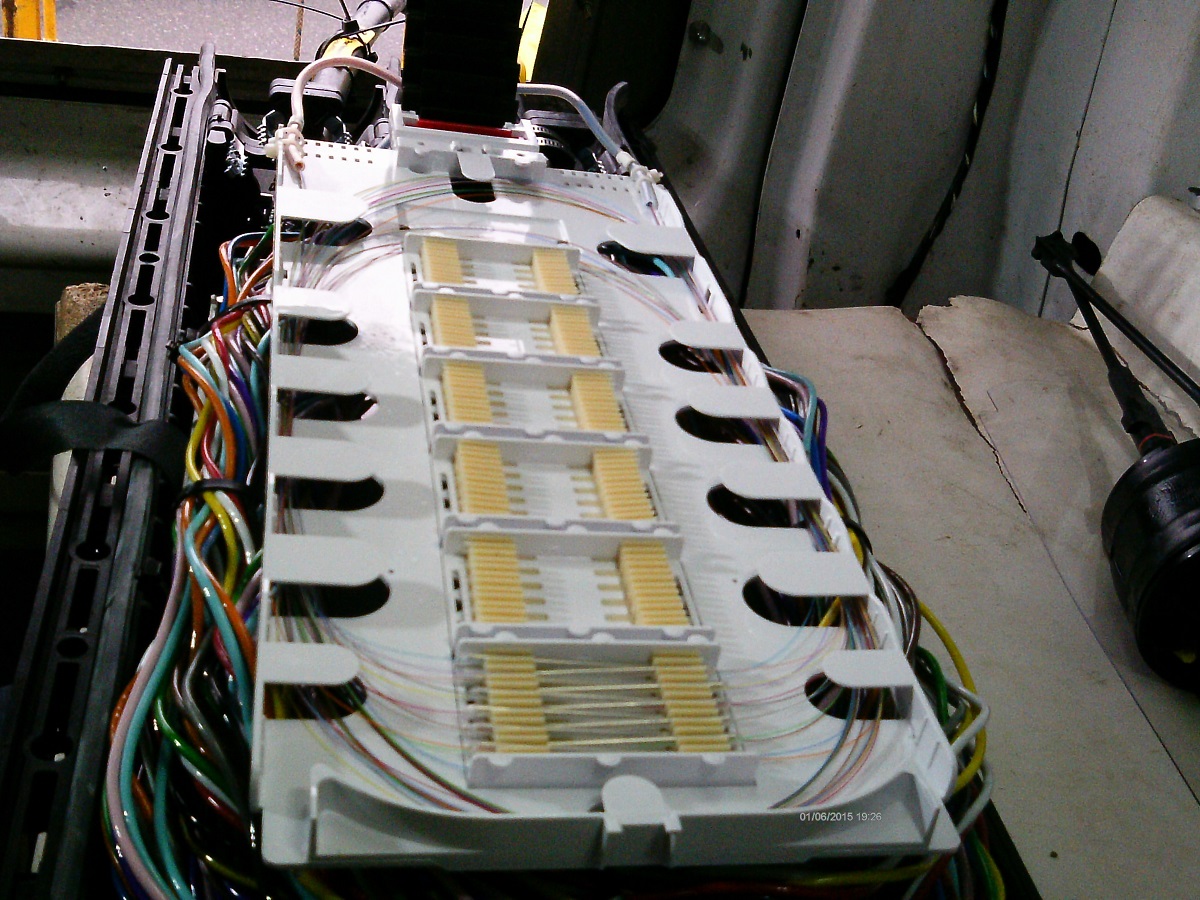

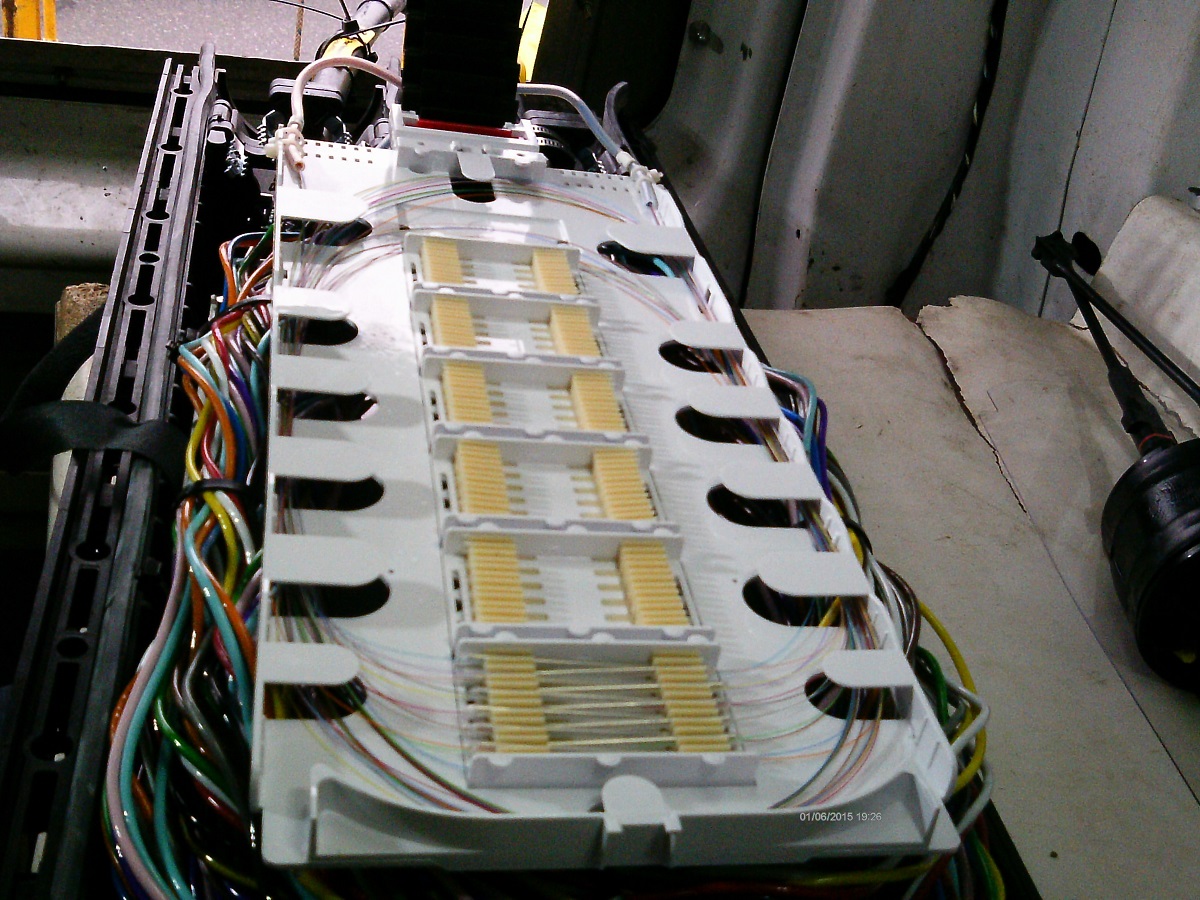

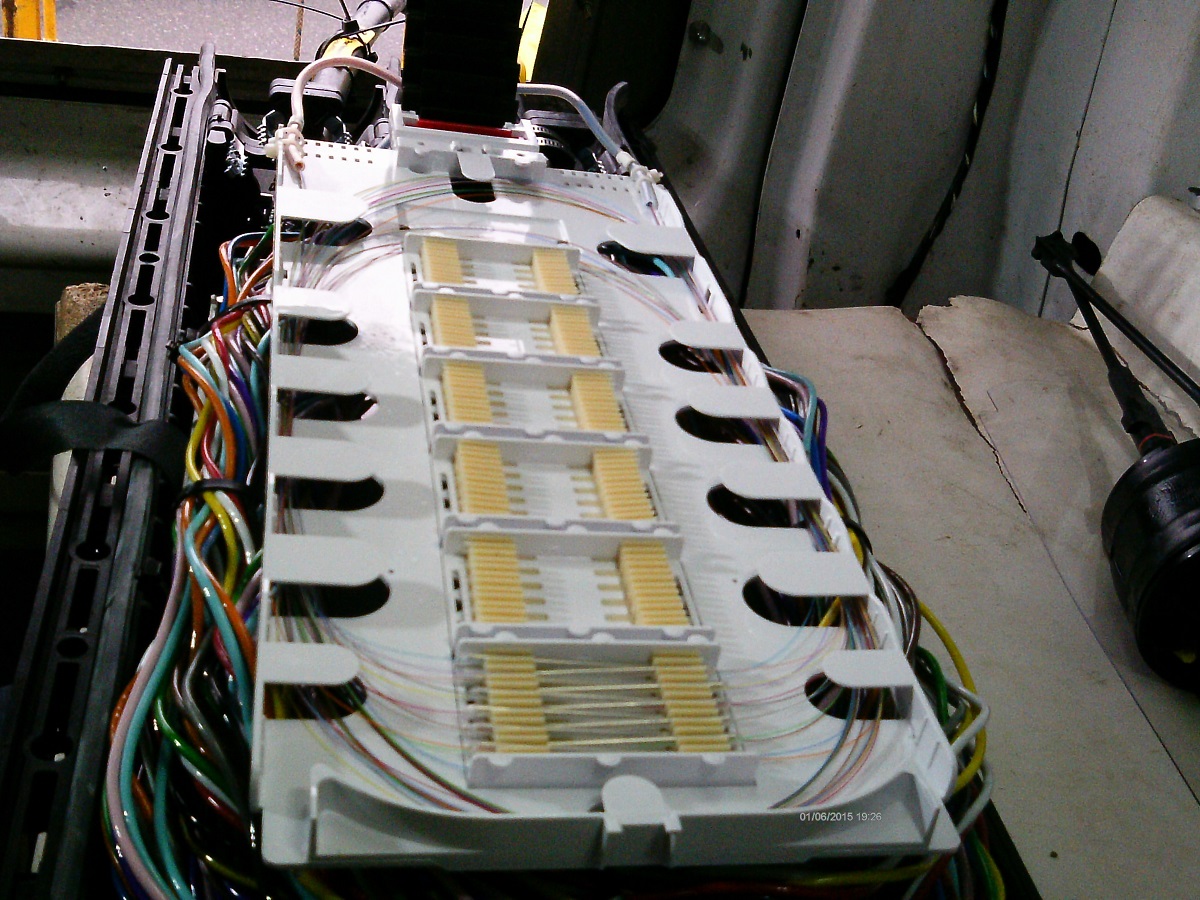

The telecommunications industry is continually changing and Competitive Service Providers (CSPs) face a challenging market. Keeping pace with regulatory requirements, increasing capacity, and improving the reliability of a network infrastructure while maintaining high levels of customer service can be an overwhelming task. The telecommunication network stands at the threshold of another era of innovation that has been fueled by the exponential growth of fixed and mobile communications. End-users increasingly demand greater connectivity and hassle-free services on-the-go. And more technologies are being developed to close the gap between the real and virtual worlds.

The telecommunication network services that we deliver here in Boston, MA together with our best-of-breed technology equipment providers, will fulfill every need of your IT and telecommunication department. Our services span design, supply, application development, testing, commissioning, support, and managed services.

To be competitive, your network delivers the highest quality of service possible. And when you can intelligently and cost-effectively upgrade and expand your network, you will be poised to benefit from growing broadband opportunities. We can fix your troublesome telecommunication environment. Professional fiber optic splicing is just one of many ways to eliminate the bottlenecks that are throttling your ability to effectively communicate. Our telecommunication network installation services is guaranteed to reduce the frustration a poor data infrastructure presents to you and your employees.

vOne of the most challenging decisions a telecommunications manager can make is choosing the proper design for an optical-fiber cabling plant. Optical-fiber cable, which has extremely high bandwidth, is a powerful telecommunications medium that supports voice, data, video, and telemetry/sensor applications. The effectiveness of the media is greatly diminished if proper connectivity is not designed into the system. Such connectivity allows for flexibility, manageability, and versatility.

Designers are aware that proper planning of a structured cabling system can save time and money. A cable that is installed for point-to-point links also should meet specifications for later upgrades as it becomes part of a much larger network. It will anticipate future applications and providing additional fibers for unforeseen applications. Also, interfacing with local service providers can also avoid duplication of cable, connecting hardware, and installation labor.

The emergence of a true service-oriented platforms has created growth opportunities for the telecommunications network. It allows service providers to introduce exciting and innovative services. All installations are fully compliant with the relevant networking standards. And workmanship is guaranteed.

For more information about telecommunication network design installations, contact ElecComm.

Joseph Coupal - Thursday, August 22, 2019

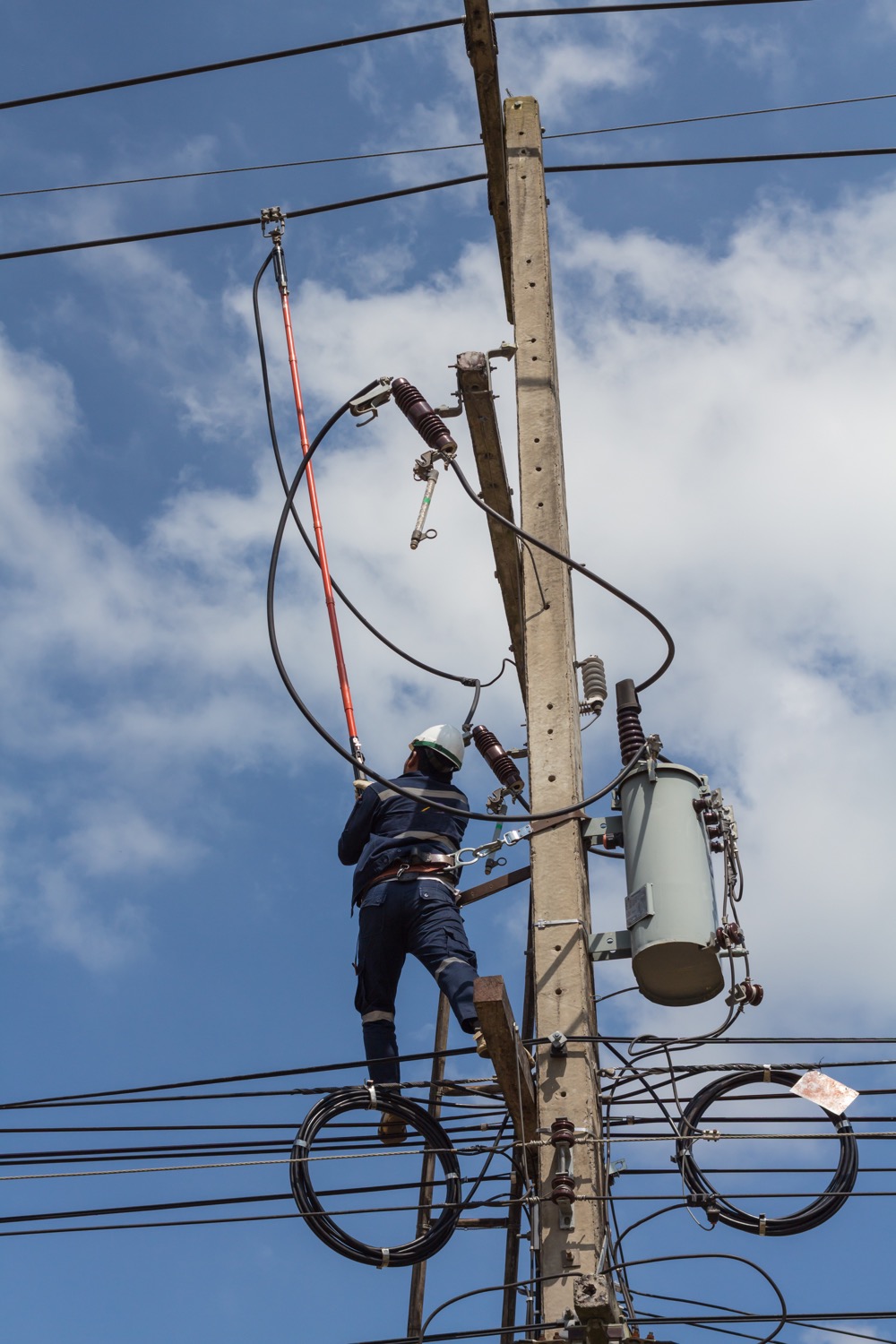

Hot sticks are insulated shaft with fittings on the ends which enable workers to adjust and manipulate live conductors and equipment from a safe distance. They come in varieties of length to serve different use and handle diverse voltage level of the charged equipment.

Today's Hot sticks are made of fiberglass. Previous designs were made from wood treated to be chemical, temperature and moisture resistant.

Here are some of the common types of hot sticks:

- Telescopic Hot Stick - are made of several hollow, tubular sections which perch inside of each other. It's top part can be extended and locked using a spring-loaded button that clicks open into a hole. It can be extended as many of the parts needed to carry out the work.

- Shotgun Stick - has a sliding lever mechanism that enables user to open and close the clamp hook at the end part of the stick. It lets the user fasten the stick to a disconnect ring then close it. The shotgun mechanism functions to unlock the hook when the switch is turned on.

- Universal Straight Stick - it allows different types of tools and equipment to be connected to the hot stick.

- Measuring Stick - provides easy and accurate method for infield measuring.

Since hot sticks are use when working with live line poles, it's important that these devices are subjected to regular hot stick insulation testing and maintenance. It must be done at least every 2 years. Seeking for a reliable testing company for electric materials, vehicle and other insulated equipment for electrical works, contact ETS Inspection and Testing Services.

Joseph Coupal - Wednesday, August 21, 2019

If you construct or maintain a golf course (or courses) throughout New England, poles and netting present strategic challenges. Every course has different dimension and requirements. Poles and netting of course are a must for the driving range, but safety mandates the need for protective netting elsewhere on the course. Consider ElecComm Inc. who has been delivering for Boston area ranges for years.

Our golf netting solutions made here in Boston, MA meet the needs of your golf requirements. Here are just some of the considerations and strategies that we will consult you on:

- Custom Size Options. Golf course has different sizes and shapes. There are offer options for pole size that caters to the exact specifications of the job. Whatever your needs, our team can make it happen with the same amount of care and precision that goes into every project we take on. Our installation is quick so you can have your netting barrier secured your driving range in no time.

- Calculated Wind Resistance. When installing netting poles to area surrounding a golf course, you require the assurance that they will stand firm among the worst conditions mother nature decides to throw your way. Golf poles are designed specifically to perform under extreme conditions such as intense wind so you can feel confident that your work on the course will remain intact.

- Maximized Life-Expectancy. The best materials are used for all installation projects to ensure the durability required for optimal functioning. All netting poles done by our team are designed to maximize the lifespan of netting barriers, and let customers feel more confident in the longevity of the projects they complete.

- Enhanced Appearance. All of the poles and netting installation done by our teams are designed to have an appearance that helps them blend into the scenery of a golf course. We can install netting poles that not only perform their function but looks great while doing so.

The materials we used last the longest and stand up to mother nature, giving you the best value for your investment. We take pride in all of the work that we do providing you only the highest quality netting poles installation in the market today. If you have inquiries or specific concerns about golf netting system, contact Elec Comm. We are glad to answer your queries.

Joseph Coupal - Friday, August 16, 2019

Businesses across Boston is upgrading their power infrastructure by installing underground high voltage cable systems. Most business owners have long accepted the long-term advantages of underground power lines and the overall value that they deliver. Clearly underground lines offer the best protection of the asset against man and mother nature. Wind, rain and snow increasingly take down dated overhead power line distribution systems. Power disruption can and should be a thing of the past.

ElecComm’s underground high voltage cable solutions across Boston, MA guarantee that companies are less likely to experience power outages and the associated cost to business operations. Both the residential developers and commercial sectors alike benefit from underground power implementation. Engineering a solution that works for you is as easy as giving us a call. We’ve been supplying Boston with underground power solutions for decades now and we are prepared to move you and your business smartly forward.

To find out more about the benefits and advantages of underground high voltage systems, contact ElecComm.

Joseph Coupal - Friday, August 09, 2019

Much of today’s business activities run through the internet. Almost every business has a critical dependency on fast and reliable internet services. It is vitally important to today’s business owner to trust the design, engineering, and maintenance of their commercial telecommunication network to seasoned professional engineers.

EleComm’s telecommunication network services here in Boston, MA guarantees state of the art internal and external communication system support. Our network solutions incorporate analysis in depth of your business’ unique operating requirements. Our systems ensure that your telecommunication network is always a business enabler when so many of your competitors and neighboring business suffer regular and recurring data challenges and outright failure.

We can fix your troublesome telecommunication environment. Professional fiber optic splicing is just one of many ways we eliminate the bottlenecks that are throttling your ability to effectively communicate. Our telecommunication network installation service is guaranteed to reduce the frustration a poor data infrastructure presents to you and your employees.

For more information about telecommunication network design installations, contact ElecComm.

Joseph Coupal - Thursday, August 08, 2019

Hydraulic cylinders are essential components of the commercial hydraulic systems of cranes, forges, construction vehicles, and agricultural machines. They are the actuating mechanical element that enables unidirectional force. Fully integrated hydraulic cylinders are used in exchange for levers and gears. The basic parts of a hydraulic system include cylinders, valves, pumps, filter and many more. Among all these component parts, the hydraulic cylinder is the component that mandates close inspection and more frequent maintenance.

Seal damage is the common cause of hydraulic cylinder failure. It results from corrosion, fitting errors, and improper metalwork clearance. The piston rod or bearings can be damaged through fluid contamination, misalignment of cylinder and load. Also, extreme temperature and chemical action can contribute to the defects. Prior to performing repair, make sure to clean the surface properly and remove the hoses and plugs connected to it. Right after taking off the components, empty all fluid within the cylinder. From here we can start the repairs for the hydraulic system. You need to prepare the following tools:

- seal kit

- rubber mallet

- screwdriver

- punch

- pliers

- emery cloth

- Torque wrench

Since leaking is the usual problem encountered in hydraulic systems, repair process involve dismantling the cylinder, proper diagnosis of the failure, faulty part repairs / replacement and cylinder rebuild. When doing this, it’s important to consider the following repair tips:

-

When dismantling the hydraulic cylinder make sure to check all components not only the faulty parts.

- Do not forget to put back the hydraulic wear bands for this guide ring will help lessen metal-to-metal contact.

- A bent or curve in the rod is an indication of an early defect of rod seals.

- Always use the right fit tools when repairing to avoid metal surface scrapes that can turn to corrosion issues in the long run.

- Be careful when handling larger hydraulic cylinder for they are utilizing high tension springs to operate.

- When replacing seals, measuring the current size of the seal is not advisable for it will expand or shrink depending to environmental condition.

Make sure to always inspect the seal, rod and bearing when performing maintenance procedure. If you notice a rough surface in the rod, this indicates the hydraulic system is imperiled. This will increase the friction so it's important to polish it to minimize rubbing and prevent corrosion. Performing regular hydraulic system maintenance and repairs will minimize defects and failures in your equipment. For more information about hydraulic system repairs, contact ETS Inspection and Testing Services.

Joseph Coupal - Wednesday, July 31, 2019

Golf netting systems are a key element of opening a golf course. Before golf vourse can open, golf nets must be installed and inspected to ensure errant balls will stay inside the range and won't pose threat to people and property in close proximity.

But before installing a golf pole and netting system, here are some helpful information for designing an effective netting solution:

- Size and dimension of the golf area

- Environmental facts which includes weather, wind speed and soil condition. Also, state and local code compliance.

- What would client prefer on the netting structure: Fixed, retractable or breakaway technology

- Pole and netting type and height

Since all golf courses have unique specifications, our golf netting solutions made here in Boston, MA meet the distinct needs of course designers. If you have inquiries or specific concerns about golf netting system, contact ElecComm. We are glad to answer your queries.

Joseph Coupal - Friday, July 26, 2019

High profile crane disasters have made national news in 2019. These are devastating stories with devastating effect on lives and corporate liability. Companies that own and deploy cranes need independent third-party crane inspection services to protect your operators, your business, and all those who work anywhere within proximity to cranes. Yes, routine crane inspection services is about so much more than regulatory compliance.

Crane companies usually stock a variety of make and models which heightens the risks for accidents. Most companies simply don’t have the expertise to be able to thoroughly test and evaluate every single model owned by the business. OSHA requires frequent recurring inspections of the equipment regardless of the type. To ensure they are operating at top condition. our crane inspection services provide for early detection of defects or excessive wear that can compromise the safety of the operator and those working near it.

We guarantee that our crane inspection and maintenance services deliver both value and peace of mind to the business owner. To learn more about routine crane safety inspection, contact ETS Inspection and Services.

Joseph Coupal - Thursday, July 25, 2019

Golf netting is a specialty service of ElecComm. We design and create sturdy golf barrier structures that will serve as a safety high barricade around your golf range property. This will prevent errant balls from escaping the vicinity and cause damages to neighboring properties.

We custom design every solution because every golf course has different dimension and requirements. Whether its a vast golf range or just a mini public course, you can count on us. Our team has been around in this industry for decades and we have implemented countless golf netting set ups, replacements and repairs across New England. We use premium quality materials that will withstand strikes and weather for years. So expect a very high standard installation of golf poles and netting at your facility that will last.

Golf operators are liable to damages related to errant golf balls. It is their lookout to ensure that their golf field and drive range is a safe place for regular games and tournaments and this includes the safety of nearby communities as well. If you need golf range netting services you can trust, contact ElecComm.

Joseph Coupal - Thursday, July 18, 2019

ElecComm's core business focus is on the installation, removal and maintenance of electric/communications distribution systems.

For almost twenty years now, we’ve served municipalities across New England with underground and overhead electrical distribution system installation, maintenance, and removal services. Today we thought we’d share with you why municipalities invest so heavily in underground power distribution systems. Here are other advantages of using underground cables:

- Appropriate in areas where overhead lines are complicated and not feasible to install

- Low upkeep required

- Minimal voltage drops

- Lower fault incidence

- Less prone to short circuits because they are less exposed to environmental elements

- Theft and illegal connection issues are reduced

- Does not endanger wildlife or low flying aircraft

Looking at these advantages, underground cable power lines offer more safe and secure power solutions for urban environments. To learn more about underground high voltage cable system, contact ElecComm.

Joseph Coupal - Monday, July 15, 2019

One of the our core competencies here at ETS Inspection and Testing Services is providing maintenance and repairs of electrical utility equipment. This includes servicing aerial devices, digger derricks, cranes and support equipment. We empower you to employ fleet services that are always in perfect working order. Our fleet services guarantee that your company meets and exceed all OSHA and ANSI requirement.

Although electrical utility fleet are procured with certified safety components, this equipment is constantly subject to damage during routine operation. They sustain damage due to in-service accidents, overloads, and fatigue. Regular fleet maintenance will eliminate operational and safety deficiencies. As it pertains to the cost of maintaining electrical utility fleet equipment, it’s a pay now or pay later reality and pay now is almost always less expensive than paying later. This translates to taking care of your equipment, your people, and your business by having a strategic maintenance plan in place.

You can also extend the life of your fleet with regular routine maintenance. For more information about fleet maintenance and repairs, contact ETS Inspection and Testing Services.

Joseph Coupal - Thursday, July 11, 2019

Earlier we blogged about the necessity to systematically maintain underground high-voltage cables. Today we’d like to expand upon that topic and get into the details of what needs to be accomplished within your preventative maintenance program. We’ll also address our approach to corrective maintenance action should cable fault ever strike your underground cable system.

Underground high-voltage preventative cable maintenance includes:

- Ground connections, cable joints and splices are inspected to verify their integrity and condition.

- Switchgears, transformers, and other above-ground fixtures are checked for cleanliness and physical condition.

- Dust and debris are removed from termination joint outer surfaces.

- Performing several tests such as contact resistance tests on terminations, insulation resistance tests between ground connections and conductors. This is done to unveil any developing damage within the system.

- Testing for defective electrical contacts and joints with infrared thermal scanning. Joints that appears to have an elevated temperature requires to be cleaned and re-torqued prior to re-testing.

Corrective maintenance is accomplished as a response to faults (e.g. damage resulting from digging, internal damaged wires, overloading, poor handling and installation, etc.). It includes:

- Inspecting electric cable routes for potential defects following an excavation.

- Insulation resistance testing to uncover faults between conductors and ground connections.

- Tracking faulty sections through the use of a sheath tester and a cable fault locator.

- Damaged electrical cable repairs, re-testing and re-commissioning.

Condition-Based Maintenance involves the inspection of underground power transmission cables and above-ground grid fixtures that have sustained partial defects. Condition-based maintenance services determine the kind of repairs that must be addressed immediately or in the near future. It’s essentially a health check-up for your high-voltage infrastructure.

For more information about underground cable maintenance process, contact ElecComm.

Joseph Coupal - Thursday, June 27, 2019

Aerial lifts must undergo recurring safety evaluations to protect both human and mechanical resources. These safety testing measures are potentially dangerous acts in their own right as it puts operators and those working near the equipment in close proximity to extremely high voltage. Dielectric testing is accomplished by supplying precise measurable voltage to the aerial devices.

Electrical current leakages is a common occurrence within all aerial devices. This can be attributed to several factors. While small quantities of electric leakages is considered safe and tolerable, certain conditions hasten the degradation of the insulating material and transcend the device into a dangerous condition. The act of degrading insulation introduces the risk of operators being subject to direct contact with high voltage current. Faulty insulation obviously can lead to serious personal injury and death. Dielectric testing and inspection validates the insulation mechanism of an aerial device whether it can handle voltage variations under normal operating conditions or not.

It is recommend that at least once year, dielectric testing must be performed. Overtime, aerial devices may receive repairs or component replacement. So frequent testing might be necessary to meet safety standards. Contact ETS Inspection and Services to check if your aerial devices are due for dielectric testing.

Joseph Coupal - Thursday, June 27, 2019

Similar to overhead transmission lines, underground electrical cables and other auxiliary equipment will fail when regular maintenance is not accomplished. The following are common issues that can threaten underground transmission line operability:

- High Pressure Fluid and Gas Filled Pipe (HPFF and HPGF) cable types or Self-Contained Fluid Filled (SCFF) electrical cable types are vulnerable to sustain fluid leakages.

- Fault in buried power cables can happen due to bare neutrals, molded joints in splices, or accidental excavation.

- Powerful winds and falling tree branches may not affect buried power cables but trees with deep root system ousting in a storm can root out underground wires.

Faults can be fixed, albeit expensively. Repairs are complicated and tedious. Prevention is a more profitable solution. Scheduled maintenance and upkeep must not be taken for granted in order to make sure the power distribution system is reliable and safe.

Contact ElecComm to discuss our wide variety of underground power cable maintenance and repair services.

Joseph Coupal - Thursday, June 20, 2019

The internet plays an integral role in all business operations, large or small. Perhaps your business’ data flow gets throttled by routine administrative demands such as video conferencing and video streaming. When this happens, all elements of your business suffer. If you have insufficient bandwidth, it’s not only your network that is slowed. Your business productivity and ultimately your profitability is throttled as well. If you have recurring and frustration slow data transfer, consider upgrading your telecommunication network through fiber optic splicing services by certified network engineers. Here are the resultant advantages of fiber optic enhancement to your network and business:

- Exceptionally High Bandwidth - Presently, no other cable material can exceed the performance of fiber optics. Copper wires are no match to the volume of data it can process and transmit per unit time.

- It Reaches Longer Distance - Signals are transmitted to a longer distance because of its low power loss capability.

- Resistant to Electromagnetic Interference - It has very low rate of bit error and its transmission is virtually noise-free.

- Absolute Data Security - Since in fiber optic transmission data are transmitted in a speed of light, it would be impossible to detect it by "listening in" to the electromagnetic energy escaping through the cable.

Business served by enhanced telecommunication fiber optic distribution process data and online transactions fast. The efficiencies gained via fiber optic splicing will significantly increase business productivity and promotes better customer service through enhanced telecommunication network. If you are interested in upgrading your telecommunication network, contact the seasoned professionals at ElecComm today!

Joseph Coupal - Thursday, June 13, 2019

Crane Inspections come in two forms -- frequent and periodic. Prior to conducting crane inspections, it is important to have a background on what type of inspection is about to be performed and what specific items are going to be checked. Both have different objectives:

Frequent Inspection Checklist

- Cranes are checked for any maladjustments which may hamper its optimal performance.

- Check for any impairment or leakage in lines, tanks, valves, drain pumps, and other air or hydraulic systems.

- Inspect for any deformation or cracks in the hook. Also, note for any unusual sound. These are included in both daily and monthly inspection. A certification record must be maintained with the inspector's signature and date during monthly inspection.

- Check the hoist chains along with its end connections for any distortion.

- Thoroughly check for any excessive wear of components.

- Check whether the wire rope reeving system is working in accordance to manufacturer’s recommendations.

- Check brakes and emergency switches whether they are operational.

Periodic Inspection Checklist

Additional inspection steps that are typically performed on an annual basis:

- Check for any deformation, cracks or corrosion of components.

- Search for loose bolts or rivets; cracked or worn sheaves and drums; worn, cracked or distorted pins, shafts, gears, bearings, rollers, locking and clamping devices.

- Look if there is an excessive wear on brake and clutch system parts, linings, pawls, and ratchets.

- Check load, wind, and other indicator inaccuracy.

- Check for any fault or unsafe power plants including exhaust leakages and emergency shutdown feature.

- Inspect for worn out chain drive sprockets and excessive chain stretch.

- Inspect electrical apparatus for any pitting or any other impairment of controller contactors, limit switches and push-button stations.

- Check worn-out tires.

For more information about crane inspection and testing services in Boston, MA, contact ETS Inc..

Joseph Coupal - Thursday, June 13, 2019

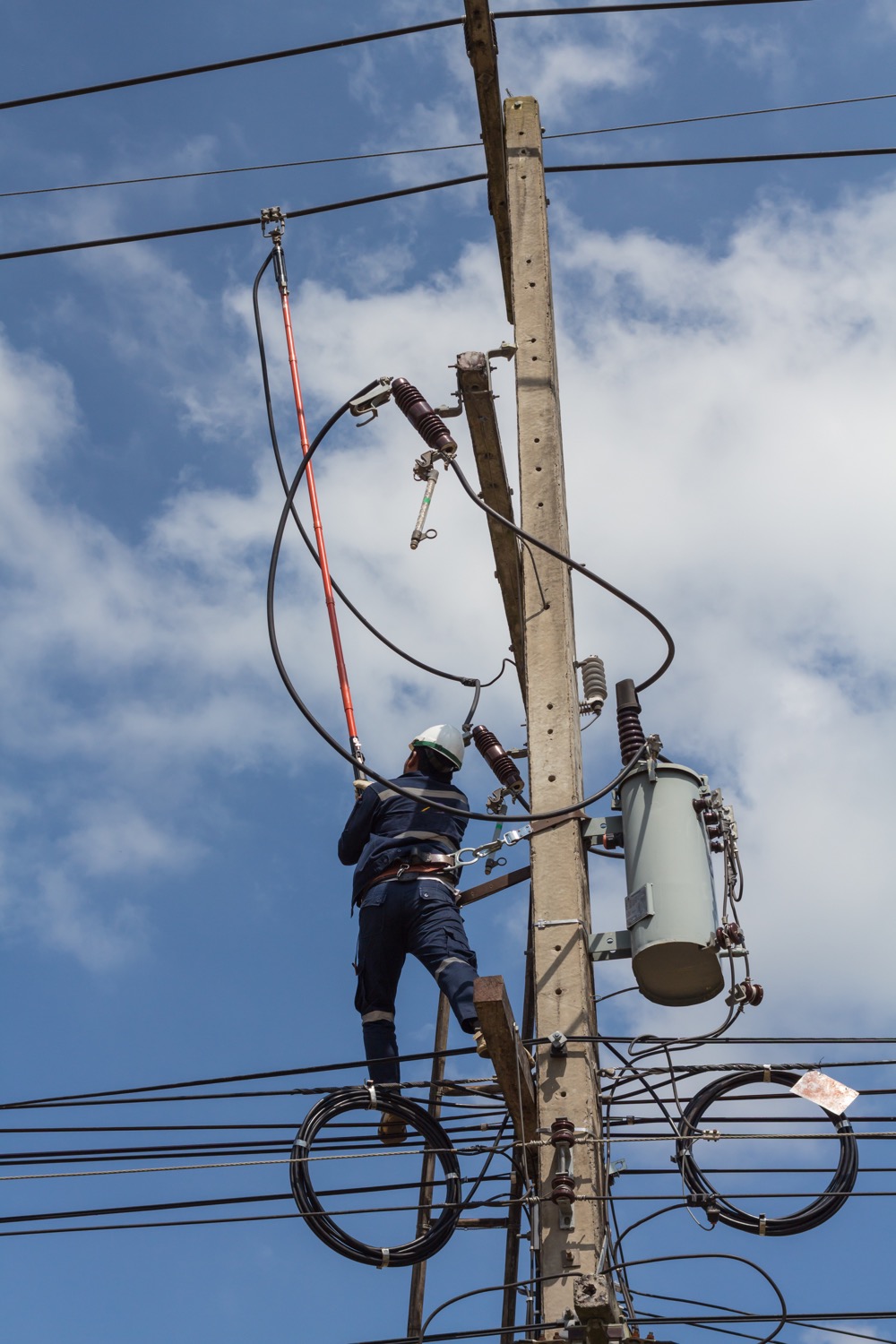

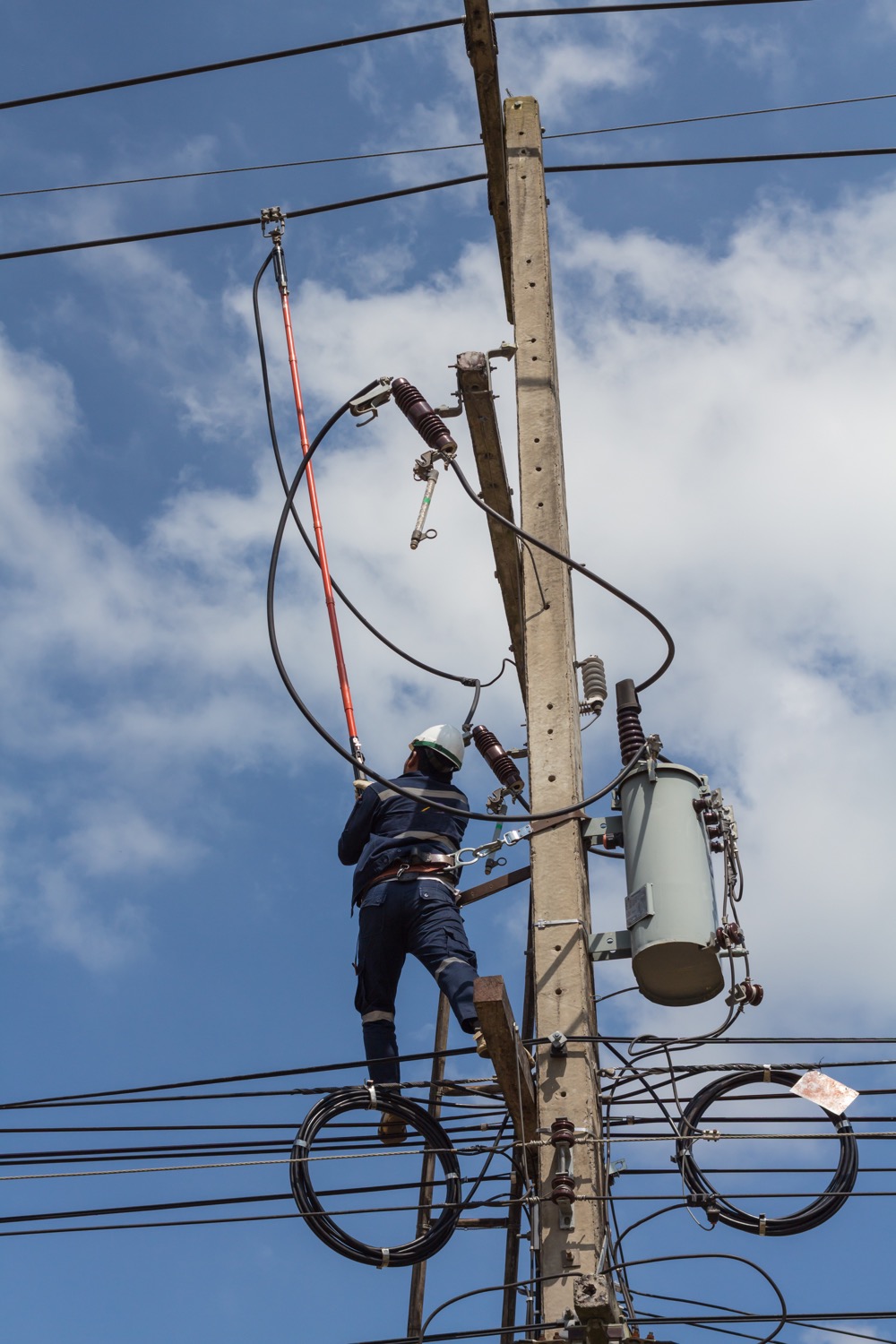

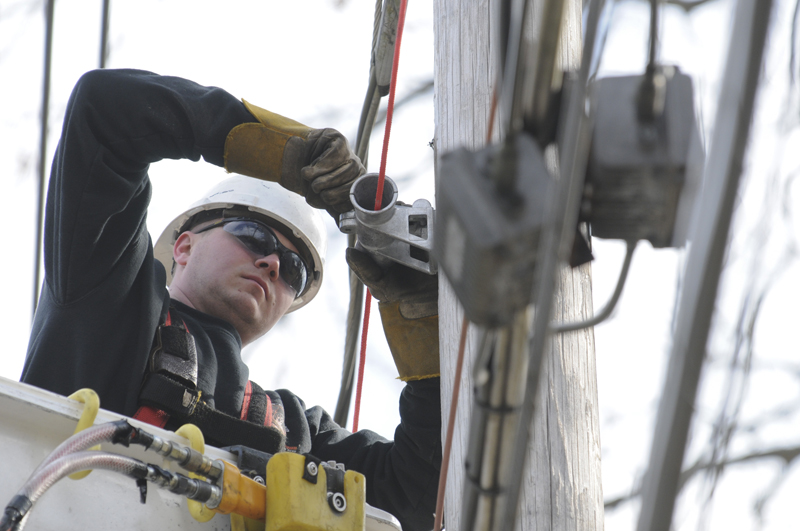

Fatal injuries associated with overhead power lines are a far too common occurrence at construction sites. It is imperative that construction workers must take preventative steps to work safely near power lines. We think that it is important for the general public to understand the safety considerations that we incorporate into our daily business service operations:

- Prior to start any work, locate first all overhead power lines.

- Keep away from all overhead power lines at least 10 feet away and this includes materials and construction equipment.

- Avoid touching anything that is in contact with the power line.

- Be careful of fences in close proximity to power lines.

- Make sure to carry high ladders horizontally so it won't reach or touch the power lines.

- Lower down cranes, excavators and other equipment apparatus before driving.

- Do not spray water near the power lines.

- Stay away from fallen power lines at least 35 feet away. Consider any downed lines as live and dangerous. Also warn others about the incident and inform them to stay at least 35 feet away from incident ground.

Whenever there's a fallen power line, report the incident right away to a power line emergency response team to repair the damaged or downed power lines immediately. In Boston, MA, contact ElecComm, we will get into your site and take proper action without delay to restore power and ensure electrical safety in your workplace.

Joseph Coupal - Thursday, June 06, 2019

When expanding an existing network or installing a new one, fiber optic splicing is done to fuse optic cables. It must be properly performed to avoid any interference in the network. There are two methods of fiber optic splicing -- mechanical and fusion splicing.

Mechanical splicing is ideal for quick or temporary fixes, but not for permanent solutions. Although mechanical splicing is easy to perform because fibers are held together by connectors, the process inherently increase the chance of insertion loss or loss of signal power. Fusion splicing, on the other hand, is commonly used for permanent splicing since it can provide the lowest insertion loss, minimal reflectance and tougher joint between the fibers.

Fusion splicing requires professional certified technicians because it's a very delicate process. When cables are not properly connected during fusion splicing, you may experience issues on the signal. Here are the steps that your certified technician employs when splicing:

- Strip the polymer coating around the optical fiber using a mechanical stripping device.

- Clean the fiber using a 99.9% isopropyl alcohol (IPA) and lint-free wipes to keep the glass free of any contaminants.

- Cleave the fiber. The cleaver notches the fiber and pulls or bend it to create a neat split rather then cut the fiber, this makes the end-face flat and perpendicular to the axis of the fiber.

- Fuse the cleaved fibers together using a fusion splicer. Align the ends of the fiber within the splice. Then, melt the fibers with an electric arc to permanently solder the ends together.

- Protect the bare fiber by re-applying a coating using a splice protector.

- Test your fiber after the fusing process using an optical time domain reflectometer to detect any splice loss or fault in the spliced fiber.

Fiber cables are fragile and require proper handling. Only highly skilled technicians can do this properly. So when you require expansion or new installation of telecommunication networks, contact ElecComm. We have the ability to engineer, manage and perform the construction, splicing, testing maintenance and restoration of fiber, copper, and hybrid fiber-coax telecommunications networks.

Joseph Coupal - Tuesday, May 28, 2019

Golf netting system is considered one of the major liability protections for golf course owners. It makes fiscal sense to invest in high quality golf poles and netting. Your legal liability as a course owner operator regarding personal injury and property damage associated with errant golf balls makes high quality golf netting one of your most sound investments.

Settling for cheap low-quality safety golf netting system will cost you more money in the end. Cheap netting often last only a couple of seasons so you will end up spending more in just a matter of few years. The reliability of your golf netting system not only depends on the quality of the materials used but the installation process as well. The installation must be properly done to ensure both longevity and safety. It takes seasoned professionals to properly conduct the installation.

To ensure your golf netting system is secure and dependable, contact ElecComm.

Joseph Coupal - Tuesday, May 28, 2019

The Hot Stick is a very important tool for linemen when working with live line poles. It is an insulated shaft usually made of fiberglass. This is the proper tool when manipulating high-voltage cable lines so electric workers won't get electrocuted while maneuvering the components of a live electric pole.

In order to ensure the safety of those using hot sticks, the device should be subjected to insulation testing prior to use. In the United States, inspection of hot sticks must be done every 2 years. The insulated stick lets the linemen fulfill all sorts of necessary work such as voltage testing, fuse replacement, open or close switches and many more without directly exposing them to the live elements. The purpose of the tool will be defeated when regular testing and maintenance is neglected. The American Society for Testing Materials Standard specifies the stringent requirements for utilizing insulated poles and these include regular hot stick inspection and maintenance.

If you are looking for a reliable testing company for electric materials, vehicle and other insulated equipment for electrical works, ETS Inc., is the right place to go to. We handle testing, minor repairs, dielectric testing, certification label, and a certified test report. Contact ETS, Inc. for more information about Hot Stick Testing and Repairs.

Joseph Coupal - Thursday, May 23, 2019

As we are now into hurricane threat season, we can't help but to be alarmed and forewarned as we look back at the disasters that transpired in recent years. Multiple power lines were downed and vast areas were affected with extended power outages.

We serve the industrial and commercial sectors to prepare for the worst case scenarios. Failure in the grid is inevitable when furious storms hits the electrical infrastructure. We need to accept the fact that there are elements that are beyond our control. But we can do something to somehow lessen its impact to your businesses. We urge customers to reinforce obsolete infrastructures or totally replace it when seen necessary for it to withstand extreme weather conditions.

Rest assured ElecComm team will continue to provide assistance to major public utilities throughout the Northeast. We can help you get ready for the worst case scenario and you can rely on our emergency response team in quick power restoration efforts. Contact ElecComm for everyday installation, removal, maintenance of overhead lines and even during emergency cases.

Joseph Coupal - Thursday, May 16, 2019

In fiber optic cable assemblies, proper crimping technique must be done with precision or else you may encounter difficulties in the next phase of the work. To attain a reliable fiber optic cable connection, proper crimping method is crucial throughout fiber termination process. At the end of the termination procedure, the cable must be pulled without detaching from the connector. The maximum pull force for each fiber optic cable connection depends on industry requirements or customer's stipulation.

When cables are properly crimped the cable assembly is strong enough to endure feasible amount of pulling that occurs during installation process. It needs to tolerate a defined degree of mechanical force even after installation. Proper crimping protects the delicate glass fiber by ensuring the force is transferred to the connection and not in the former.

Regardless how advance the tool is, it is in the crimping technique that defines the reliability and long-term performance of the optical connection. It is a skill and only a certified personnel with years of training can accurately perform the technique. In order to ensure the quality of your fiber optic assembly, hire only reputable and proven service professionals.

ElecComm engineers are expert in this field. Our workforce is highly skilled and cross trained in order to perform every aspect of telecommunication network jobs. Contact ElecComm for construction, splicing, testing maintenance and restoration of fiber, copper, and hybrid fiber-coax telecommunications networks.

Joseph Coupal - Wednesday, May 08, 2019

Aside from dielectric inspections and testing, ETS provides repair services for basically any hydraulic component. This includes hoses, pumps and valves. Our hydraulic repair services encompasses small to large-scale industries.

Prior to any repairs, we dismantle and clean parts. Then the units are submitted for inspection and diagnosis. We ensure that all fittings are checked for precision and tolerance. We list the components that are damaged and in need of replacement. We provide price quotation to our customers after our evaluation is completed.

Only skilled professionals recondition, replace, and install hydraulic parts. At ETS, we have highly-trained technicians who deliver quality hydraulic unit repairs for you. So if it is hydraulic issues that you need, you come to the right place. Contact ETS Inspection and Testing Services for hydraulic repair inquiries.

Joseph Coupal - Tuesday, May 07, 2019

With the golf season is in full swing, there's a growing concern of the safety of those situated in close proximity to the fairways. Errant golf balls cause personal injury and damage to property. Golf club operators are legally liable when this unfortunate scenarios crop up. In order to prevent accidents in and out the golf course, operators rely upon durable golf range netting.

When driving range poles and netting becomes your need, ElecComm is at your service. We provide you the highest quality golf nets that will serve as protective barrier to secure your golf course and prevent accidents to neighboring facilities as well. We have served golf course owners for years now and have the advanced knowledge along with right equipment to guide you through the process of installing and repairing your golf netting system.

Our golf nets are made of premium quality material and we guarantee our installation services. Contact ElecComm for rough estimates of your golf net requirement.

Joseph Coupal - Sunday, April 28, 2019

Last year's nor'easter disaster in Massachusetts was devastating. It rummaged innumerable properties and affected numerous businesses. Significant power outages lasted for over two weeks as countless power lines were downed.

More than 360,000 customers in MA were without electricity. ElecComm dispatched 24 people to help with the restoration procedure as quickly as possible.

As hurricane season kicks in once again, we can't help but look back upon what occurred last year. We’re prepared for repeat unfortunate events and compel us to constantly improve our contingency management plans. We highly recommend our customers do the same to improve and insure their business continuation in the event of repeat disasters. We encourage them to upgrade obsolete infrastructures so it won't easily break down in extreme weather condition.

Rest assured ElecComm is here to assist our customers at all times in any electrical issue they may encounter. You can rely on our quick response team to repair damaged lines and restore power immediately. Contact ElecComm for power infrastructure maintenance, repairs and emergency situations.

Joseph Coupal - Thursday, April 25, 2019

Prior to using live-line tools and aerial equipment, it is important that these devices receive professional dielectric testing and certification. This provides the assurance that the equipment can deliver sufficient protection to thoroughly protect electrical workers working in their hazardous environment. The equipment must meet the technical and safety standards as specified by OSHA and ANSI.

ETS Inspection and Testing Services exists to provide the proper tools and professional technicians that deliver dielectric testing services for your live-line devices, aerial lifts and bucket trucks. We guarantee quality and economical dielectric testing services across the greater Boston area. In order to prevent downtime within your business’ operation, it’s imperative that you be on top of your annual equipment maintenance and certification. Through the testing and inspection procedure, hidden issues can be detected earlier so necessary repairs can be done to prevent further damage of the equipment.

For more elaborative details on dielectric testing procedure, don't hesitate to contact ETS, Inc. We will provide you with all the necessary information you need prior to testing process.

Joseph Coupal - Sunday, April 21, 2019

Public safety is everyone's concern and responsibility. There are many when people whose main responsibility is to ensure public safety are faced with difficult challenges. One of those challenges is downed power lines. Downed power lines are not only a safety threat but power outages radically effect the entire populous. Municipalities and power companies often turn to the professionals of ElecComm to rapidly address downed power lines.

Downed or damaged power lines pose serious threats to the public. As soon as a downed power line is seen, companies repairing downed power lines should be called right away so that expert electricians can come over and see what they can do about the situation.

There are several reasons as to why and how electric power could be knocked down. It is commonly due to severe weather conditions such as storms and hurricanes which result in broken utility poles and broken power lines lying on the ground. These downed lines may still be live and can cause electrocution to any passerby. That is immediate power line storm response service is imperative. They can prevent these threats from happening and these cases from worsening.

The earlier the remedy, the better. Immediate restoration of power in the affected area is vital. Businesses resume normal operations thereby sparing them from any further financial and opportunity loss. Having poorly maintained electric poles and power lines is definitely a recurring threat to the continuity of power service.

It is equally important for municipalities and businesses to conduct regular repair and maintenance to overhead power lines in Wilmington, MA as part of safety procedures of power utilities. Doing so will help ensure that the power lines are a hundred percent up to standards and so related accidents will be kept at bay.

To find out more about the importance of repairing downed power lines for public safety, contact ElecComm.

Joseph Coupal - Sunday, April 14, 2019

Since the dawn of the internet, the technology has become a staple for every business. Strong and stable internet connection is foundational to gaining cutting edge competitive advantage. Because of this, the business telecommunication network engineers in Plymouth, MA are continuously finding ways to develop and improve their systems. These networks are not just all about having reliable service but also deliver upon the ever increasing need for increased band width. Recent innovations empower telecommunication engineers to employ fiber optic splicing for both new and network enhancement configurations.

Given the growing number of businesses that have become highly dependent on the internet, fiber optic splicing was developed as a solution to such increasing need and demand for a better connection and transmission. Switching from copper wires to fiber optic cables guarantees better bandwidth without jeopardizing the speed of transmission. With the help of these fiber optic cables, increasing bandwidth and keeping the connection stable have become a breeze.

Incorporating fiber optic splicing during telecommunication network design installations is imperative when one wants to achieve faster and higher bandwidth. It is important to note that when switching to fiber optic cables, the assistance and service by the experts in the industry are as equally important. This method is new and should only therefore be performed by a professional. This is to ensure that the cables are perfectly spliced according to the configuration unique to your application. Otherwise, these fiber optic cables or the telecommunication networks as a whole will not serve their purpose.

To find out more about how businesses can benefit from fiber optic splicing in telecommunication network design installation, contact ElecComm.

Joseph Coupal - Sunday, April 07, 2019

Increasing municipalities are implementing underground high voltage cables because they are ultimately more practical and cost effective when compared to overhead power lines. The predominance of underground high voltage lines’ value corresponds to dramatically reduced maintenance costs. Given the innovative techniques in detecting and repairing faulty underground high voltage cable networks (UHVC networks), repair and maintenance can be accomplished efficiently by experts which means less downtime is only needed for any of these services to be done.

Our underground power line solutions never stop improving over time. Major utility companies, communication service providers, and others find it more practical to run high voltage cables underground due to the improved safety of the assets vs overhead line installation. The professionals at ElecCom excel at underground high voltage cable installation across all of Boston, MA. We serve the smallest of Boston companies to the largest to include NSTAR Electric, Western Mass Electric, National Grid, and many others.

To find out more about cost-effective, safe, and reasonable solutions to underground high voltage systems, contact ElecComm.

Joseph Coupal - Friday, April 05, 2019

Annual Dielectric Testing and Inspection is an important safety measure to ensure aerial devices are working in perfect condition and operating safely. These devices are highly complex and threatens severe operator injury and avoidable repair expenses when electric and mechanical issues go undetected an unaddressed. The yearly gear inspection and evaluation will mitigate these threats.

ETS Inc. specializes in dielectric testing and inspection services for aerial lift trucks and digger derricks. Commercial aerial lift trucks and digger derricks are governed by OSHA and ANSI protocols. One primary inspection focus area is the insulation status of the apparatus. Dielectric testing validates the contraption's electrical strength and voltage. This is done through application of voltage across the insulation material of the gear while metering the resultant leakage current.

It not a matter of IF you need dielectric testing services but WHEN you will need them. Choose your testing service provider with the proven record and years of experience to protect your staff, your equipment, and your reputation. We are certified OSHA and ANSI service providers. We guarantee a quality inspection and will provide you a comprehensive evaluation of your equipment.

Contact ETS Inc. for more information about Dielectric Testing and Inspection.

Joseph Coupal - Thursday, March 28, 2019

Fiber optic splicing is a high-demand telecommunication network systems support service. Data communication network degradation simply can’t be tolerated in today’s competitive business environment. For a host of reasons, sub-sections of a data networks become problematic which require professionals to quickly isolate and apply mechanical fiber optic splicing.

Our mechanical fiber optic splicing services here in Boston, MA perform a similar function to conventional cable splicing but with one major difference. Fibers are merge together by mechanical coupling rather than using welding techniques for non-fiber cables. In a mechanical splice, two cleaved fiber tips are mechanically aligned to each other by a special housing. The protective housing ensures fiber ends are steady and enable signals to stream freely between them without difficulty.

Here are the upsides of utilizing mechanical fiber optic splicing:

- No power supply is required.

- No extra tools are needed apart from a fiber stripper and fiber cleaver

- A good alternative in cases where fusion splicing is not viable.

- It can be done within a couple of minutes and is ideal for temporary connections.

For more information about mechanical fiber optic splicing, contact ElecComm.

Joseph Coupal - Thursday, March 21, 2019

The rise of residential and commercial construction in today’s economy is simply remarkable. The demand for commercial power infrastructural support and new electric line construction is equally on the rise as aging electrical infrastructure approaches the end of its lifecycle. The electrical professionals at ElecComm are the trusted source for new construction projects throughout the greater Boston area in need of new supporting electrical infrastructure.

Commercial and residential expansion electrical needs are not limited to electric line. Phone lines and internet connections are also core to new developmental projects. So in addition to underground high voltage cables we support your development project with electrical services of any kind.

For large scale electric construction works across New England, ElecComm is (and has been) the trusted source provider for decades. Our crews are certified electrical technicians and linemen with proven years of experience and excellence in the field. We guarantee quality service and timely delivery of all our electric construction services.

Don't hesitate to contact EleCcomm for your new electric line construction or current infrastructure reinforcements.

Joseph Coupal - Thursday, March 14, 2019

Golf courses are increasingly being located in close proximity to residential and commercial areas. Although these areas are strategic for the course owners and the golfers themselves, close proximity to commercial and residential buildings pose risks to neighboring facilities as errant golf balls can and will cause damage and/or personal injury. Course managers must ensure that sturdy and reliable golf range netting must adequately partition golf range and errant shots from going outside the course.

When high quality golf driving range netting is needed, ElecComm is your go-to. We provide installation of poles and netting for golf driving ranges and golf courses along with replacement netting. We only use premium quality range nets to ensure errant golf balls to stay inside the golf area. We also make sure that the golf netting system is well-constructed and securely installed as an effective preventative measure against injury or property damage associated with stray golf balls.

We guarantee that our golf range netting set-up can hangs tough against constant strike of heavy golf balls, harsh weather conditions, exposure to environmental elements, and other stresses. Since diverse golf ranges have different needs and dimension requirements, we accept design customization.

For more information about our golf range netting services, contact ElecComm.

Joseph Coupal - Thursday, March 07, 2019

It is undeniable that the internet made numerous trades and dealings quick, convenient and efficient. No wonder various transactions nowadays are done through the internet. Precisely for this reason, a telecommunication network failure for a long duration of time is intolerable particularly in the business sector.

Any telecommunication network outage results at the very least lost productivity from your work force. Any prolonged network outage renders a situation of not only lost staff productivity but other forms of revenue killing effects of network denial of service. When your business network goes down, your first call should be to ElecComm’s telecommunications repair team to promptly restore connectivity and return to profitable business operations. You can count on ElecComm's 24/7 telecommunication network repairs and services because we’ve been delivering professional network restoration services for decades.

ElecComm team is comprised of certified technicians who are skilled and equipped with specialized tools and devices for troubleshooting and repairing telecommunication network outges. Aside from doing maintenance and repairs, you can also tap our team for communication line construction, splicing, testing maintenance and restoration of fiber, copper, and hybrid fiber-coax telecommunications networks.

So the next time you need assistance on telecommunication network system in Boston, MA, contact ElecComm.

Joseph Coupal - Thursday, February 28, 2019

The demand for reliable/uninterruptable power systems is driving the ever increasing need for underground transmission lines. Underground high voltage system installation services is an ElecComm core competency and has been for decades.

In addition to the core need for eliminated environmental-caused power line failure, municipalities and business entities choose to burry cables to eliminate the “eyesore” of above ground power lines. Municipal planners increasingly prioritize the natural beauty of their community. We help beautify communities in Boston and across the greater New England area.

Our underground high voltage cable systems incorporate upscale protective gears and advanced fault detection systems. In the event of critical scenarios, engineers can promptly take action because electrical glitches can be accurately monitored using innovative time domain reflectometry device.

ElecComm is the team you can count on in terms of expertise in underground high voltage cable system. If you are interested in upgrading your electrical infrastructure, we can assist you with the new layout, installation and maintenance. We have the right skills and equipment to perform the job.

Contact ElecComm to find out more about underground high voltage cable system.

Joseph Coupal - Thursday, February 21, 2019

Golf course managers need to stay ahead of their member’s game. That means making course upgrades as required throughout the calendar year. Winter is the perfect time to assess course safety equipment such as poles and nets. Winds, wildlife, and cold weather are just a few things that take their toll on your course’s safety measures.

ElecComm’s golf course poles and netting provide the long-lasting protective barrier between errant shots and innocent bystanders. In today’s litigious society, one of the first things injured parties investigate is the condition of basic course safety equipment. Course managers want long-lasting poles and nets to prevent avoidable injury to people and damage to personal property.

The strategic layout and placement of poles is critical to properly secure the entire golf range. ElecComm is there for any course manager’s need for pole installation and netting. For more details about our golf course protective netting and pole service, contact ElecComm today.

Joseph Coupal - Thursday, February 14, 2019

In today’s high-tech business environment, your business’ data network is by default one of your single most valuable business assets. IT managers keep a keen eye for data network upload and download speeds. Accordingly, increasing numbers of New England business owners turn to us here at ElecComm for telecommunication network maintenance. We have a proven track record of delivering faster and more stable internet connection via our fiber optic splicing expertise. Fiber optic splicing empowers you to remove data “bottlenecks” from your business’ data network.

Fiber optic cable is sensitive equipment that can and does break and most often at the worst possible time. We specialize in installing and maintaining fiber optic telecommunication networks. Advanced fiber optic telecommunication network design and installation is a highly technical undertaking that requires the expertise of certified technicians. It is important to tap certified technicians to handle your job. If you need (or even suspect) a need for telecommunication network service, contact the proven telecommunication network professionals at ElecComm.

Joseph Coupal - Thursday, February 07, 2019

In winter, power line support heightened their alert for power outage occurrences. This is due to increase of power line issues that take place during frigid weather. More particularly to old electrical infrastructures that are drastically vulnerable to a freezing climate.

Aside from that, it is expected that energy consumption do spike in winter due to almost non-stop use of heating systems in both residential and commercial setting. This makes it rather difficult to measure the accurate amount of energy required to produce in response to the increased demand. When load forecasting is not precised, power interruptions or rotating blackouts are imminent in widespread areas just to deal with tremendous overloads.

Power system malfunction can be somehow mitigated by reinforcing or upgrading old infrastructures. Meanwhile, upgrading the load forecasting system to a more advanced technology can be beneficial in the distribution level.

For prompt power line repairs, maintenance and electrical infrastructure upgrades, contact ElecComm.

Joseph Coupal - Wednesday, January 30, 2019